Zerspankraft

spike® – sensorischer Werkzeughalter made in Germany

Fertigung aus einer Hand Unser sensorischer Werkzeughalter spike® ist made in Germany. Alle unsere Produkte werden vor Ort in Kaufbeuren im Allgäu herstellt. Somit kann die gesamte Fertigungskette an einem Standort gebündelt werden, wodurch unsere gewohnte Qualität gewährleistet werden kann. Die Mitarbeiter, die an den einzelnen Produktionsschritten beteiligt sind, kennen sich bestens mit dem Gesamtsystem…

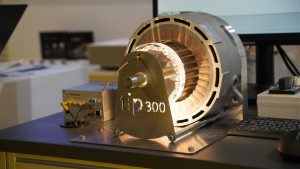

Weiterlesentip_300 Sensorik auf der CWIEME 2022 in Berlin

Mit der tip_300 Sensorik auf der CWIEME 2022 Vielen Dank für die zahlreiche Besuche unseres Standes auf der CWIEME 2022 in Berlin. Das Produkt tip_300 hat bei vielen Besuchern ein großes Interesse geweckt. Wir hatten spannende Gespräche rund um die Vorteile unserer tip_e-motion Sensorik und freuen uns sehr, weitere Prüfstände damit ausstatten zu dürfen. Warum…

WeiterlesenSchleifdruck überwachen mit spike® – GrindTec 2022

So war die GrindTec 2022. Wir haben uns sehr über interessante und spannende Gespräche gefreut, die sich um spike® und dessen Einsatz in der Prozessanalyse, Schleifscheibenentwicklung,Prozessüberwachung, Kühlschmierstoffanwendung und weiteren Bereichen drehten. Besonders das Überwachen des Schleifdrucks mit spike® war ein Highlight. Schleifdruck direkt an der Schleifscheibe erfassen mit spike® Nutzen: Erkennung von… Beispiele – PDF…

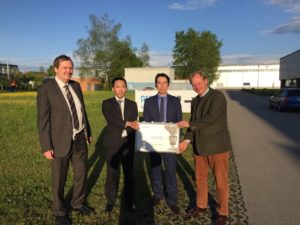

Weiterlesenspike® international – Japan und Thailand

Im Mai 2017 haben unser neuer spike-Partner in Japan, Fukuda Corp. und die pro-micron Geschäftsführung eine enge und partnerschaftliche Zusammenarbeit unterschrieben. spike® wird weiterhin international wachsen und ist nun über Fukuda Corp. zu erwerben. Seit November 2017 ist der spike® nun außerdem neben Japan auch in einem weiteren asiatischen Land, Thailand, vertreten. Mit unserem neuen…

Weiterlesen