Press release

spike® – sensory tool holder made in Germany

Manufacturing from a single source Our smart tool control system spike® is made in Germany. All of our products are manufactured on site in Kaufbeuren in the Allgäu region. Thus, the entire production chain can be bundled at one location, which ensures our usual quality. The employees involved in the individual production steps are very…

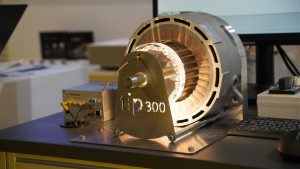

Weiterlesentip_300 sensor technology at CWIEME Berlin 2022

With the tip_300 sensor technology at CWIEME 2022 Thank you for the numerous visits to our booth at CWIEME 2022 in Berlin. The product tip_300 has aroused great interest among many visitors. We had exciting discussions about the advantages of our tip_emotion sensor technology and are very pleased to be able to equip further test…

WeiterlesenMonitoring grinding pressure with spike® – GrindTec 2022

That’s what GrindTec 2022 was like We were very pleased about interesting and exciting discussions, which revolved around the spike® and its use in grinding wheel development, process analysis, process monitoring, cooling lubricant application, and other areas. Measure grinding pressure directly on the grinding wheel Benefit: Detection of… Examples – PDF Technical data sheet -…

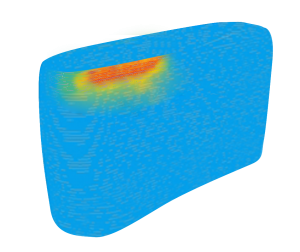

WeiterlesenRelease of the new Software-tool spike®_map

We are proud to present the new spike_map. You can see how to solve daily challenges for components with high quality requirements:

WeiterlesenA new device for the pro-micron Tec-Centre

New equipment delivery from Rego-Fix The new Rego-Fix powRgrip PGU 9800 finds its new home in the Tec-Centre of pro-micron. We are looking forward to having the tool clamping system in use with us in the future. This device is another important component for further developing our spike®_mobile. The powRgrip® tool holder in combination…

WeiterlesenExciting presentation by pro-micron at the HSM in Darmstadt

The pro-micron GmbH was represented at the HSM in Darmstadt This year’s “High-Speed Machining Conference” took place in Darmstadt on 26 and 27 October. The focus was on future digitalised machining and cutting. The event was very well received by numerous international and national participants. Exciting research contributions, industry impulses and personal discussions were…

WeiterlesenDiMaP – HYBRID concept with DiMaP trail at EMO Milan

Hybrid event on the topic of digital machining After a successful DiMaP 3.0, participants met again at EMO in Milan. Visitors were able to follow DiMaP’s trail in order to talk face-to-face with DiMaP partner companies about digital machining use cases. This now makes DiMaP even more user-specific. For detailed illustration, scenarios specially adapted…

WeiterlesenSpectacular return to the trade fair world

First online – then at EMO.

We are thrilled by the combination of traditional and online trade shows.

DiMaP 3.0 goes Hybrid

Digital Machining Market Place – DiMaP GOES HYBRID

DiMaP 3.0 from 21st-24th of September 2021 – How the machining industry turns DiMaP into a format that combines the physical trade show with a digital event

When the wireless sensor systems company pro-micron GmbH from Kaufbeuren initiated the first DiMaP conference in March 2020, the motivation was purely to compensate for the lack of trade show opportunities during the Corona phase. What was first intended to be a presentation vehicle for companies offering digital machining solutions, quickly turned into something much larger, much more strategic and most importantly, something driven in a spirit of close cooperation along the machining value chain. After the kick off DiMaP in July 2020, DiMaP 2.0 followed in March 2021 in a larger and even more professional format.

pro-micron vaccination campaign meets with great media interest

“Herd immunity” – Would we achieve the “magical value”? The corona virus continues to keep the world in suspense. In order to contain the effects of the virus – including on the economy -, according to experts, ideally the so-called “herd immunity” helps. Base on expert’s estimation, this will be achieved in Germany if around…

Weiterlesen