References

Convince yourself and read about the experiences of our renowned customers in the references!

Together with our partners along the value chain

spike®-references

100% quality control

Setting the standard in digital machining together with our partners along the value chain.

What customers say about smart process monitoring with spike® in metal cutting

"The product spike®_mobile from the company pro-micron (www.pro-micron.de/spike) has been successfully integrated on several series machines in the meantime and the rollout on all machines is running.

Due to the very good experiences from this project, I recommend this solution to customers with the need of detecting the sporadic error. It increases our process capability to a level not previously achieved."

- René Kehl, Key Account Manager, Heule Werkzeug AG

Type of use

spike®_basic as a diagnostic tool for tool development

Benefit

spike® as developent tool for the own tools

Details

spike® - global standard in tool development

„Kennametal was founded in 1938 and belongs to one of the most innovative tool manufacturers worldwide. With the sensory toolholder spike® we found a globally usable and standardised development tool in order to compare our tools at the different locations worldwide. This is how it is possible for us to also offer innovative machining tools to our customers in the future. In our company the spike® established to the standard for tool development of the drilling, milling and grinding technology. In our opinion spike® is also a useful tool for process control for the in-process 100% quality control for our customers, but also for our partners and universities in order to increase the understanding of processes.“

- Thomas Voit, Senior Engineer Process Engineering R&D Material Science, Kennametal Shared Services GmbH

- Herbert Kauper, Dipl.-Ing. (FH), Global Holemaking Systems Engineering, Kennametal Shared Services GmbH

«by this time the sensory measuring holder spike® is a essential component in our tool development. In machining study with endmills occur high dynamical forces and moments, which we can record accurate with spike®. That’s how a tool can be evaluated even better. With the help of the tool analyzer, important informations about the installed tool, that we need for our product development and optimization can be obtained.

Quality and technial progress is a important core value in our company and with pro-micron as a partner, wer are on our right way.»

Michael von Büren, experimental mechanic in the test centre of the company Fraisa SA

Dr. Frank Müller, Head of Design and Development, explains how CHIRON Group uses the data of spike®, in order to increase toolpiece quality and productivity, use the full potential of a machine and reduce production costs.

Thanks to the wear detection of each cutting tool in real time you can…

- Use machine lifetime optimally

- Reduce setting-up effort

- Prevent tool breakage

spike® with DMG Mori

- Type of use:

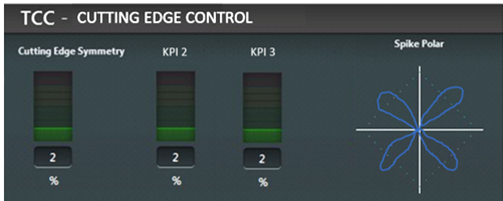

integrated in spindle in the TCC - Benefit:

spike® as spike_inspindle for the force-based dynamic tool change - Details:

spike® as TCC at the HMI is integrated in the Celos sidescreen with the pro-micron Tool Control Center-app.

- Type of use:

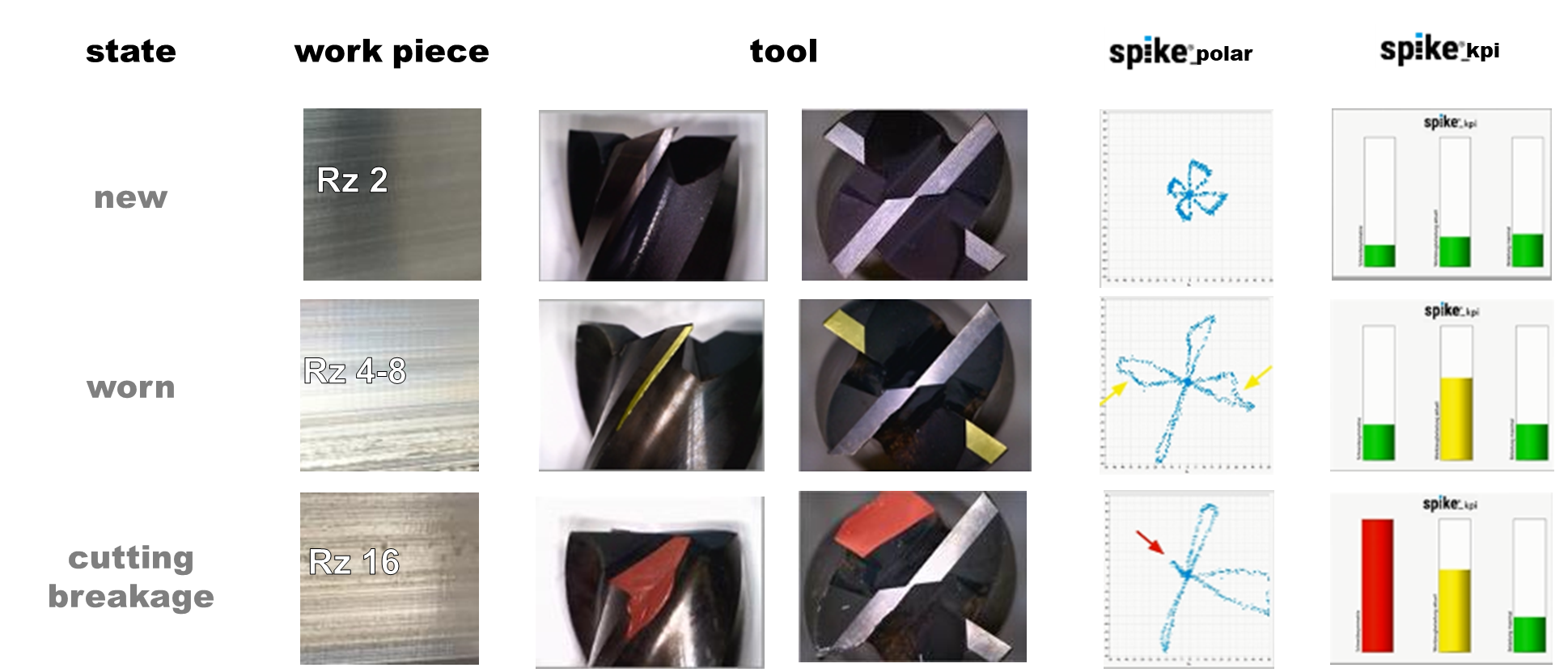

„With spike® as a sensory tool holder or as a spindle-integrated variant in our TCC, we pragmatically make it easier for our customers to make their way to Industrie 4.0 production. If only one of the tool cutting edges is worn out, we can force-controlled and replace the sister tool in a timely and fully automated manner to ensure surface quality and at the same time make full use of tool life. Integrated into out Celos interface, the machine operator or process optimizer can use the spike®__polar to see the cutting edges live and automatically report major changes”.

„With spike® as a sensory tool holder or as a spindle-integrated variant in our TCC, we pragmatically make it easier for our customers to make their way to Industrie 4.0 production. If only one of the tool cutting edges is worn out, we can force-controlled and replace the sister tool in a timely and fully automated manner to ensure surface quality and at the same time make full use of tool life. Integrated into out Celos interface, the machine operator or process optimizer can use the spike®__polar to see the cutting edges live and automatically report major changes”.

- Alfred Geißler, executive director Deckel, Maho Pfronten GmbH

spike® with Bosch

- Type of application:

Series monitoring in surface process - Benefit:

100% quality control - Example:

spike® on powRgrip® basis is connected with the connect_advanced from pro-micron via Profibus with the machine control and uses the spike®_bending moment for the qualitatively successful execution of the machining process - 24/7.

"With spike® and its ability to absorb even the finest bending moments in the series process in powRgrip, we can ensure the high and increasing quality requirements in surface machining that our customers expect from us in 24/7 production.

The proactive and efficient project planning with the machine and tool suppliers involved by the team at pro-micron should also be emphasized here."

- Stefan Wagner, Head of Process Development Machining, Robert Bosch GmbH

spike® with Hoffmann Group

- Type of use

tool development and process qualification - Benefit

spike® as a development tool for own production - Details / conducting

Generic spike®_kpi during tool manufacturing

„Since 2006 we are working intensively with spike®_mobile as a sensory tool holder in our sectors tool development and process qualification at several Hoffmann locations.

With spike® we can prove our customers objectively the capability of our tools on the basis of the measured bending moment- and axial force data with spike® polar.

As a connect_advanced version with connection to the machine control, spike® opens totaly new possibilities to control quality-sensitive processes in the industry, from which our universal machine user can prove as well.

With the intelligent spike®_kpi algorithms we enable our customers to go new ways process overarching.“

- Olaf Linke, Director Business & Product Services Hoffmann Group

„As the responsible speciality department at the MTU Aero Engines for machining technology, we were looking for a suitable force-analysis-system, that makes us conduct process analyses in the manufacturing fast and flexible without big setting-up effort. In our perspectivce spike® fulfilled these needs. The difference between spike® and products from other providers is the relatively manageable setting-up effort with a good and sufficient information quality. With spike® we expand and improve our analytical ability and reaction time for all problems in the manufacturing environment. We can recommend spike® to industrial users in small and middle-serial productions.“

„As the responsible speciality department at the MTU Aero Engines for machining technology, we were looking for a suitable force-analysis-system, that makes us conduct process analyses in the manufacturing fast and flexible without big setting-up effort. In our perspectivce spike® fulfilled these needs. The difference between spike® and products from other providers is the relatively manageable setting-up effort with a good and sufficient information quality. With spike® we expand and improve our analytical ability and reaction time for all problems in the manufacturing environment. We can recommend spike® to industrial users in small and middle-serial productions.“

Stefan Müller - Process specialist machining processes, MTU Aero Engines

„The spike® sensory tool holders are the ideal supplement to our in-house 4.0 solutions just as the process monitoring system toolscope.

„The spike® sensory tool holders are the ideal supplement to our in-house 4.0 solutions just as the process monitoring system toolscope.

Even with very fine processes with the smallest tool and small mechanical pressure, detailed data can be raised. This enables a even more comprehensive process monitoring.

As a tool manufacturer we have the sensory tool holder from pro-micron in usw both in our own tool manufacturing and in the development.

Beside the inquiry of the mecanial data, spike® enables us the measurement of the temperature in the tool grain. With these dates we can optimate the quality of our tools.“

- Gerhard BAILOM, Managing Director

spike®_assist – your entrance to the world of digital machining.

You are interested in 100% quality control even with an entry level budget? Making the tool’s condition easily visible to the machine operator – this is exactly what you can achieve with spike®_assist.

Siemens Energy in Berlin already received their solution.

spike®_assist gives them access to a live visualization of each and every one of the tool’s cutting edges.

Process errors such as drill run, vibrations or asymmetric tool wear can be easily detected without any further analysis. Discover the entrance into the world of digital machining – spike®_assist.

Many thanks to Markus Zapke and Siemens Energy for the good cooperation.

These customers also use the spike® smart cutting force measurement system.

to remain competitive in the age of Industry 4.0.

Together with our partners

We are working more closely together as a value chain through the digital machining marketplace

and are setting the standard together.

tip_300-references

OUR CUSTOMERS WORLDWIDE:

Tier-One-suppliers

![]()

Top 5 of

truck manufacturers worldwide

![]()

Top 5 motorcycle manufacturers in Europe

Top 10 of E-car manufacturers worldwide

![]()

Aircraft industry

Formula 1

![]()

Tooling industry

Train industry

Tier-One-suppliers

![]()

Top 5 of truck manufacturers worldwide

![]()

Formula 1

![]()

Aircraft industry

Top 10 of E-car manufacturers worldwide

![]()

Top 5 motorcycle manufacturers in Europe

train industry

Tooling industry