Willkommen bei pro-micron

DEN STANDARD SETZEN

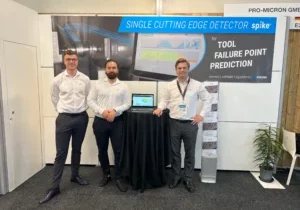

... in der digitalen Zerspanung mit

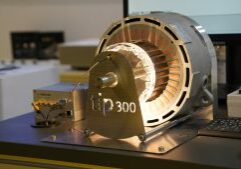

...in drahtloser Temperatur-

messung mit

ZUSAMMEN MIT UNSEREN PARTNERN ENTLANG DER WERTSCHÖPFUNGSKETTE

Wofür wir stehen

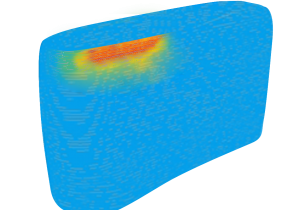

pro-micron GmbH steht für innovative und drahtlose Sensorsysteme. Dabei erstreckt sich die Produktpalette der pro-micron GmbH von drahtlosen und passiven Temperaturfühlern im Bereich Automotive und Food & Beverage bis zur drahtlosen intelligenten Zerspankraftmessung. Die Produktsparte spike® hat sich in der zerspanenden Branche etabliert und bietet seinen Kunden durch zukunftsweisende Hard-und Softwarelösungen einen Weg hin zur smart Factory.

Namhafte Kunden wie Bosch und Miele sprechen uns seit Jahren Ihr Vertrauen aus. Genau dieser enge Kontakt zu unseren Kunden und Partnern entlang der gesamten Wertschöpfungskette lässt unsere Experten maßgeschneiderte und zukunftsorientierte Sensorsystemlösungen hervorbringen. Unser Anspruch für die Zukunft ist es weiterhin, mit smarten Sensorsystemlösungen unseren Kunden zukunftsweisende Produkte zu bieten.

Pro-micron's Geschäftsbereiche

UNSERE BRANCHEN

Automotive

Aerospace

Werkzeug- und Formenbau

Zulieferer

E-Mobilität

Lebensmittel