Neues von pro-micron

Bleiben Sie informiert und verpassen Sie keine Neuigkeit:

- Presseinformationen

- Messeberichte

- Aktuelles

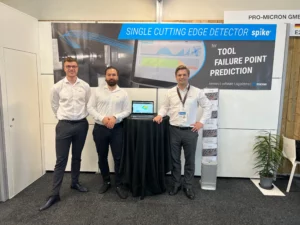

Kennen Sie Ihre tatsächliche Werkzeugstandzeit? Dieser Frage ist unser spike® Team auf den Grund gegangen. Die Ergebnisse und weitere neue Entwicklungen rund um die spike®-Modellreihe präsentierte unser Messeteam vom 18. – 23. September auf der EMO in Hannover. In Kooperation…

Mehr LesenUnser spike® Messeteam war erneut unterwegs, dieses Mal ging es nach Frankreich zur SIAE Paris Air Show in Le Bourget im Norden von Paris. Unser Fokus bei dieser Aerospace-Messe lag vor allem auf dem Thema Tool-Failure-Point Ermittlung in der CFK-Zerspanung.…

Mehr LesenWir waren mit unserem pro-micron Messeteam auf den Hochschulmessen in Augsburg und Kempten auf der Suche nach neuen Talenten. Mit unseren einzigartigen Messedemonstratoren haben wir vielen interessierten Student:innen gezeigt, was uns bei pro-micron ausmacht. Innovative Technologien, spannende Arbeitsfelder und sehr…

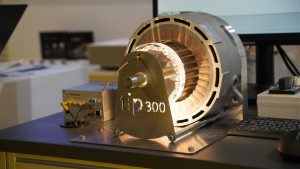

Mehr LesenCoiltech Augsburg 2023 – Recap Am 29. und 30. März war es wieder so weit. Wir waren mit unserem tip_300 Sensormodul unterwegs auf der Coiltech in Augsburg. Wie auch schon auf vergangenen Messen war unser einzigartiger drahtloser Sensor ein Highlight…

Mehr LesenAuf geht’s, der Spaß beginnt! – das war unser Motto als wir am Freitag dem 10.02.2023 unser pro-micron Teamevent gestartet haben. Eine Wanderung, abendliches Rodeln und natürlich gutes Essen durften dabei nicht fehlen. Und für Abenteuerlustige gab es die Möglichkeit am Folgetag noch Skifahren zu gehen.

Mehr LesenFertigung aus einer Hand Unser sensorischer Werkzeughalter spike® ist made in Germany. Alle unsere Produkte werden vor Ort in Kaufbeuren im Allgäu herstellt. Somit kann die gesamte Fertigungskette an einem Standort gebündelt werden, wodurch unsere gewohnte Qualität gewährleistet werden kann.…

Mehr LesenMit der tip_300 Sensorik auf der CWIEME 2022 Vielen Dank für die zahlreiche Besuche unseres Standes auf der CWIEME 2022 in Berlin. Das Produkt tip_300 hat bei vielen Besuchern ein großes Interesse geweckt. Wir hatten spannende Gespräche rund um die…

Mehr LesenSo war die GrindTec 2022. Wir haben uns sehr über interessante und spannende Gespräche gefreut, die sich um spike® und dessen Einsatz in der Prozessanalyse, Schleifscheibenentwicklung,Prozessüberwachung, Kühlschmierstoffanwendung und weiteren Bereichen drehten. Besonders das Überwachen des Schleifdrucks mit spike® war ein…

Mehr Lesen