Drahtloser und passiver Temperatursensor tip_300

Ihre Vorteile durch tip_300

- Messbereich bis 300°C

- Bis zu 6 Sensoren gleichzeitig

- Drahtlos über mehrere Meter

- Innerhalb von elektromagnetischen Feldern möglich

- In rotierenden Anwendungen

- In metallischer Umgebung

- Ohne Batterie oder Energy-Harvesting

- Signalübertragung im 2,4 GHz ISM_Band

- Verschiedene Sensorformen

- Individuelle Antennen

Unsere tip_300 Applikationen

tip_300 – drahtlose Temperaturmessung durch Surface Acoustic Waves

Anwendungsbereiche – SAW des drahtlosen Temperatursensors

- Temperaturüberwachung in Elektromotoren

- Rotierende Objekte

- Bewegte Oberflächen

- Elektronikfertigung

- Backstraßen

- Trockenöfen

- Vakuumanlagen

- Thermische Prozesse

- Elektrische Leiter

Einsatzmöglichkeiten – SAW des drahtlosen Temperatursensors

- Zustandsmonitoring

- Temperatur-Profiling

- Traceability in der Produktion

- Prozessregelung

- Schwellen- und Grenzwertüberwachung

Vorteile – SAW durch die drahtlose Messung

- Live-Signalübertragung

- Einsparung von Verkabelungsaufwand

- Einsparung von Messzeit

- Reduzierung von Stillstandzeiten für Messungen

tip_300 in Action: drahtlose Temperaturmessung mit bis zu 6 Sensoren für raue Umgebungen

tip_300 im E-Motor

Temperaturinformation zu den Magneten wird benötigt, um eine thermische Schädigung der Magneten im Rotor zu vermeiden und so den Einsatz günstigerer Magnete zu ermöglichen. Unser drahtloser und passiver Temperatursensor hilft dabei, die Genauigkeit der Regelgüte zu verbessern und damit die Effizienz im Fahrzyklus zu erhöhen, die Leistungsausnutzung zu maximieren (Vermeidung von Derating) und (thermische) Reserven zu minimieren.

tip_300 im Lötofen

In Kondensationslötanlagen vom Typ Condenso X der Firma Rehm Thermal Systems. Bei demunter der Bezeichnung WPS 2.4 (Wireless Profiling System)erhältlichen Systemwurde der Sensor am Warenträger integriert. Damit wird eine Prozess-Traceability von 100%, also lückenlose Überwachung jedes durchgeführten Lötprozesses erreicht.

- Optional in Neuanlagen

- Zum Nachrüsten als Retrofit-Version

tip_300 in der Küche

Auf der Kitchen & Bath Industry Show in Las Vegas stellte Miele das Produkt „Wireless Precision Probe“ vor. Exklusiv für Miele entwickelt und produziert pro-micron einen auf SAW-Technologie basierenden Sensor in Serie, welcher als exaktes drahtloses Speisethermometer fungiert und mit dem Ofen kommuniziert, der aufgrund exakter Dateninformation die Temperatur automatisch regelt. So wird egal welche Speise auf den Punkt gegart.

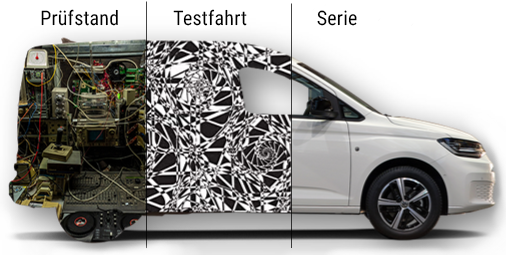

Rotor-Temperaturmessung live auf der Straße:

Diese Kunden nutzen bereits unseren drahtlosen und passiven Temperatursensor in Ofenanwendungen

tip_300 Ansprechpartner

Produkt und Service

Hubertus von Zastrow

Geschäftsführer pro-micron

+49 8341 9560 - 50

tip_300(a)pro-micron.de