Single Cutting edge detector spike®

for TOOL FAILURE POINT PREDICTION

Your partner on the path to autonomous machining

With its spike® technology, pro-micron offers its customers a path towards autonomous machining.

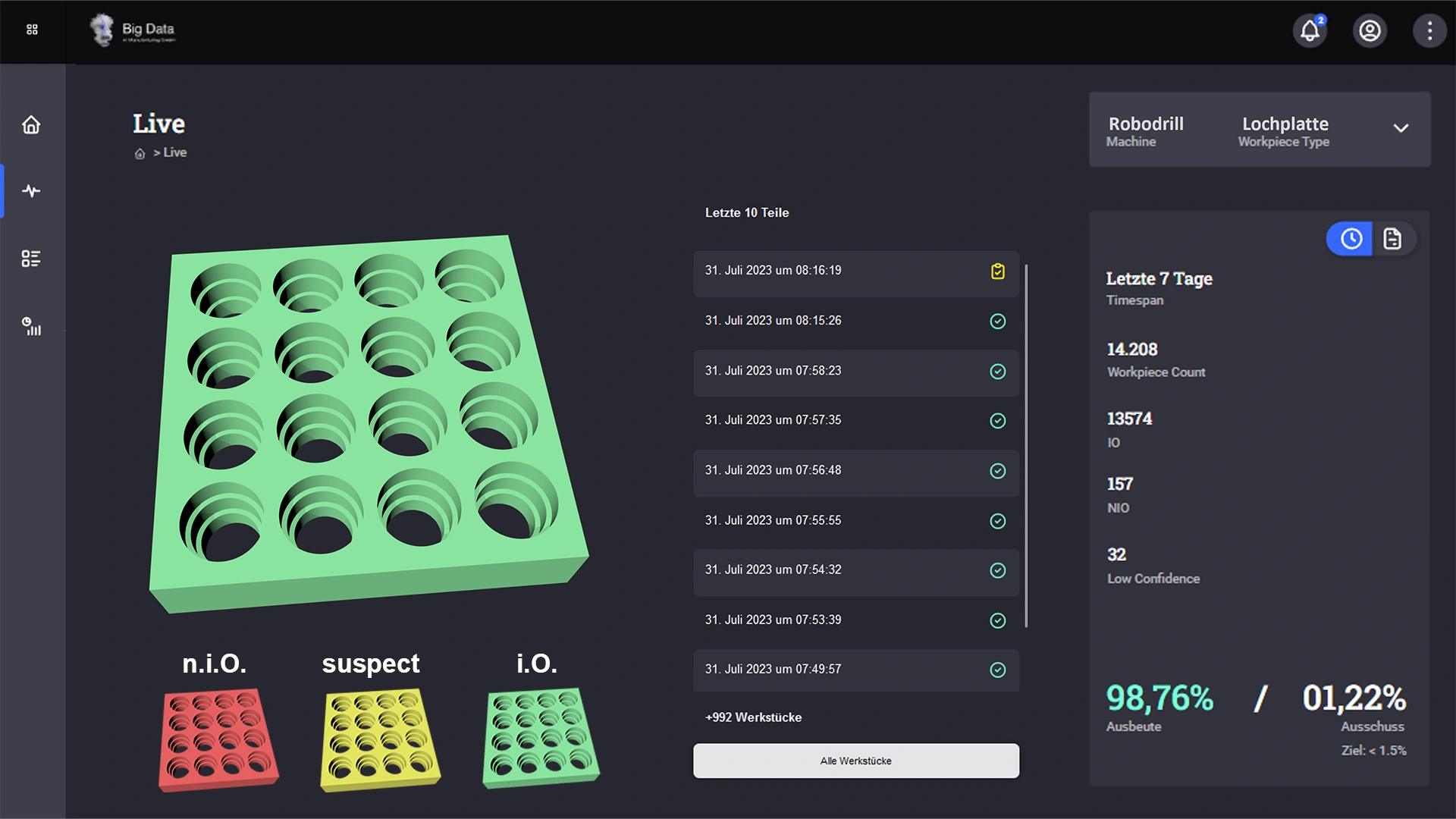

Smart sensors with most sensitive, unique signals as well as advanced software tools which track, synchronise and

edit process and machine data, enable our customers not only to analyse and to monitor their (serial) production but also to predict quality results in real time using AI algorithms.

Strong partnerships of companies along the value chain make this possible.

Our technology

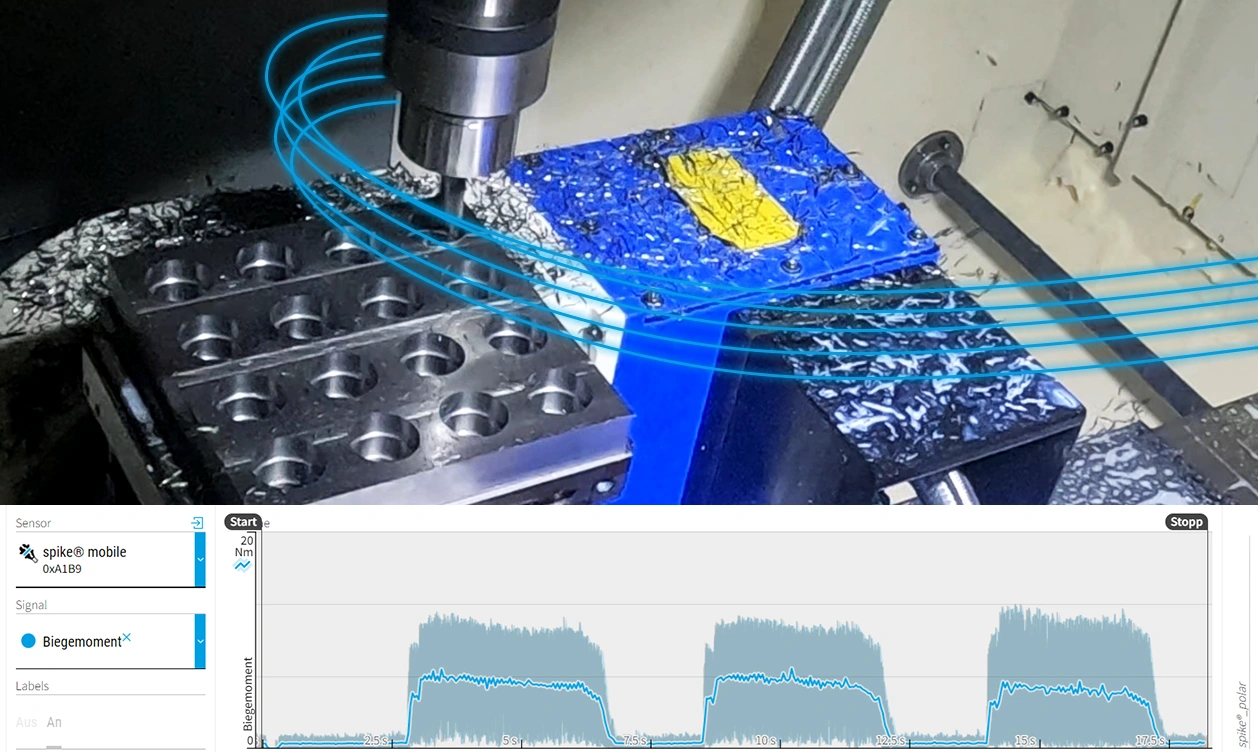

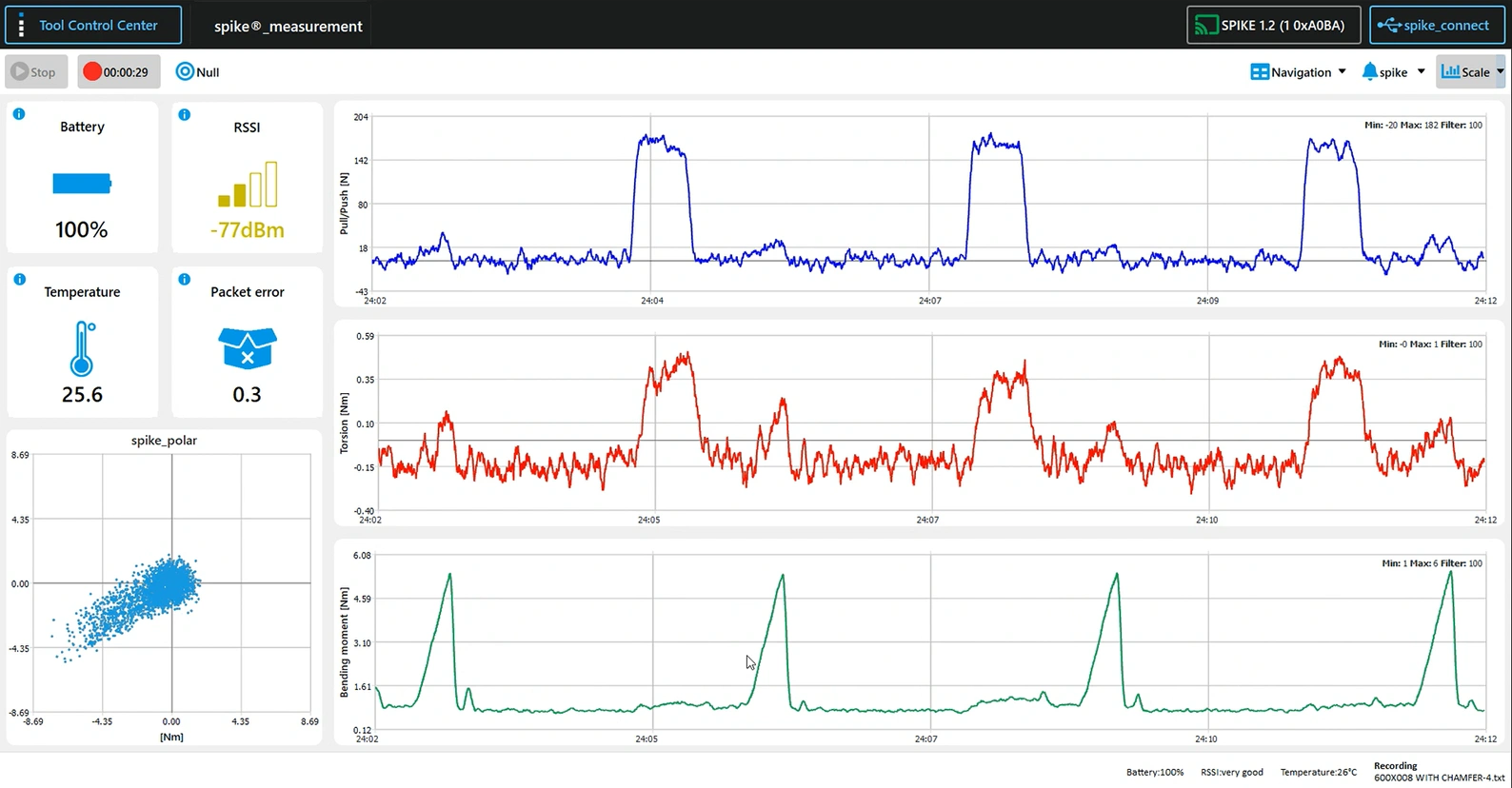

PROCESS DATA TRACKING

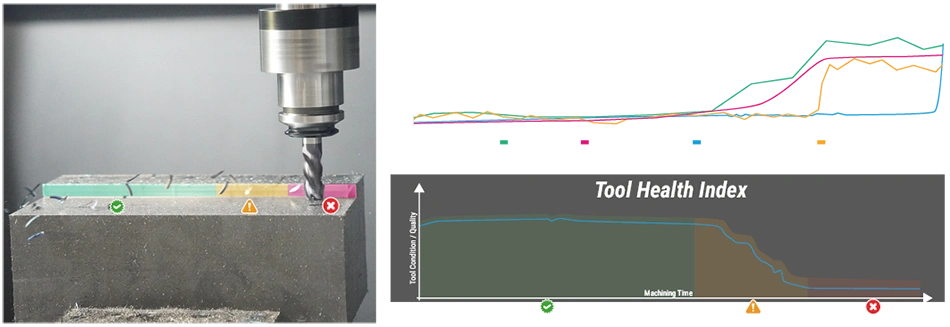

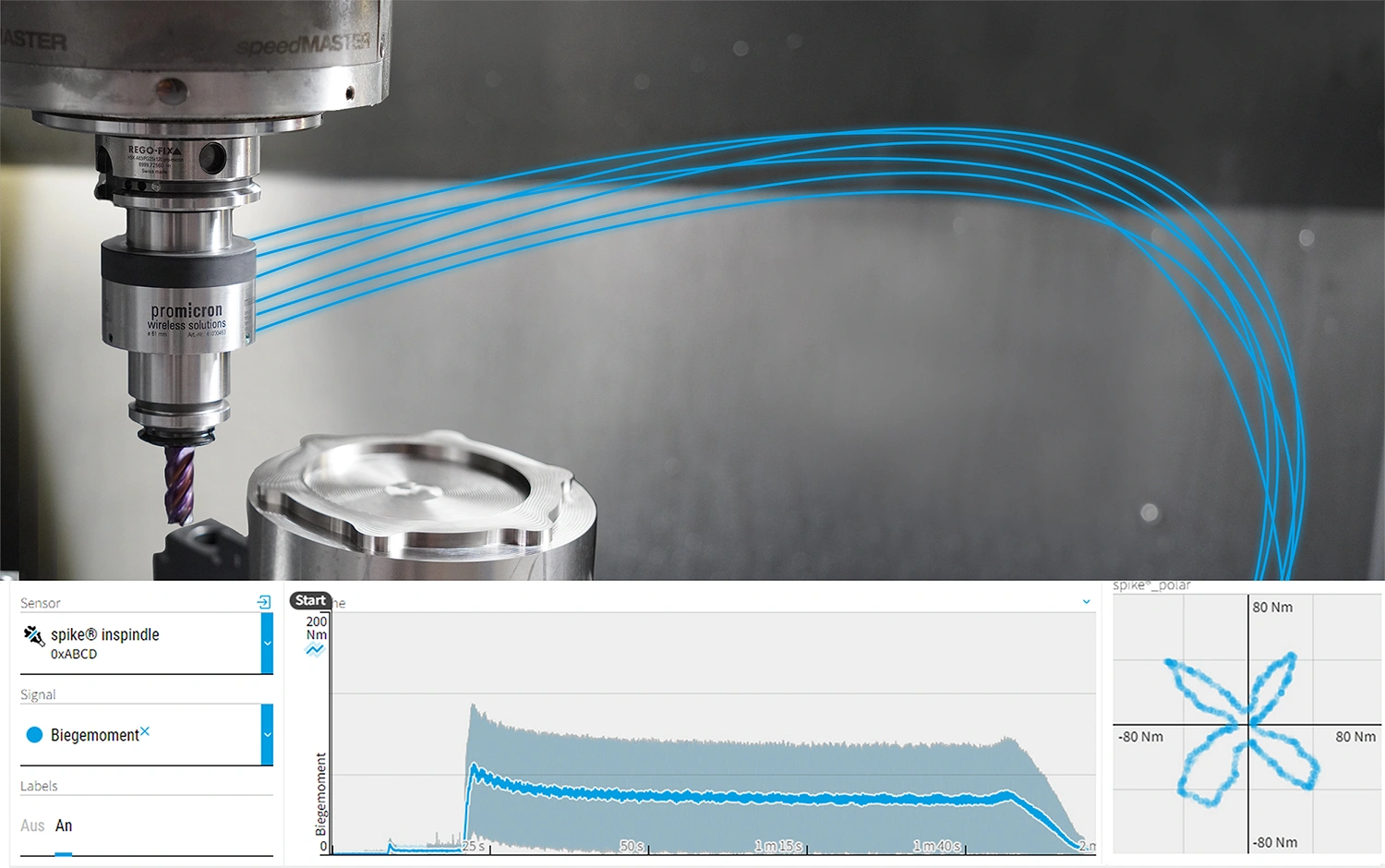

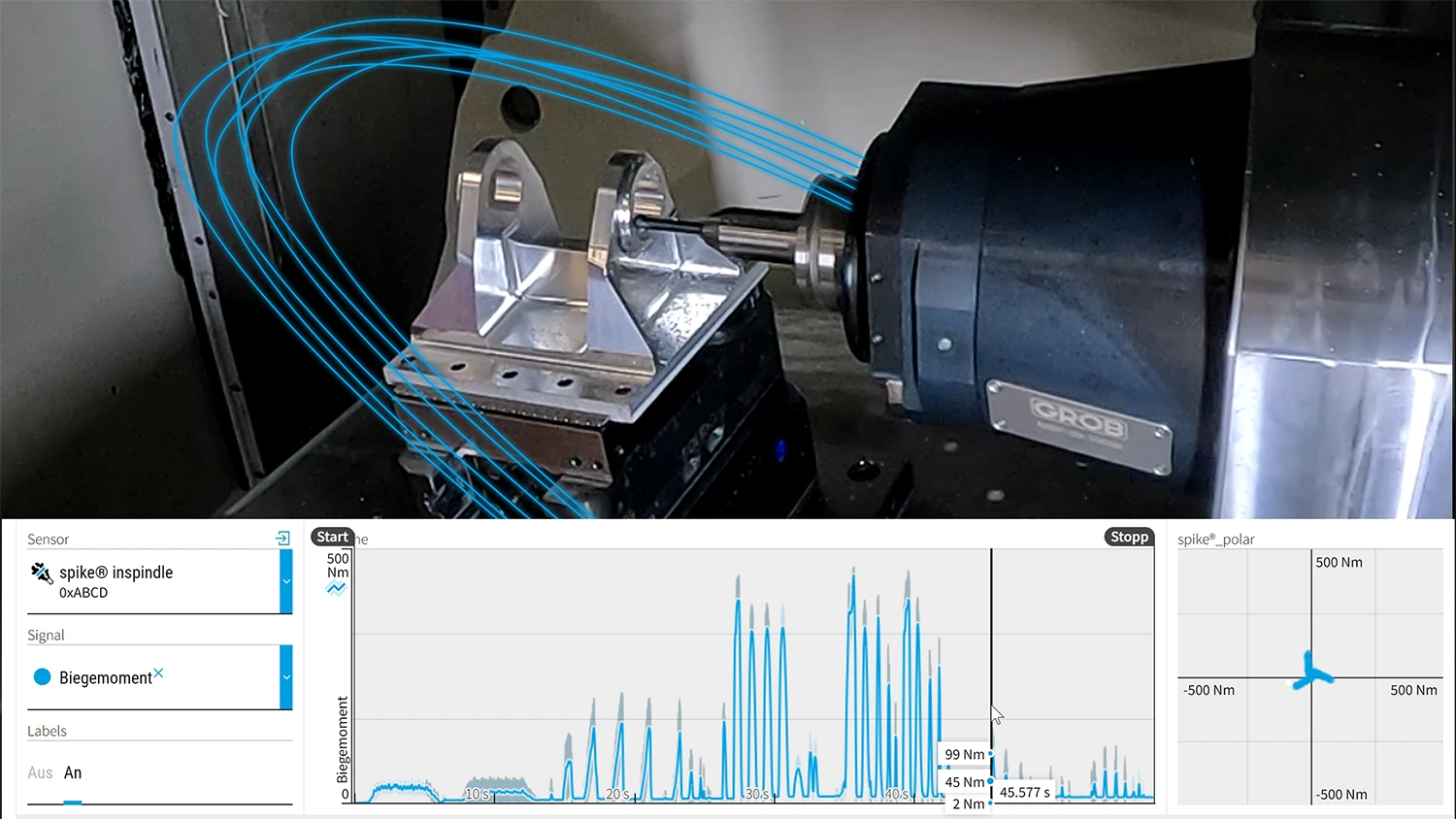

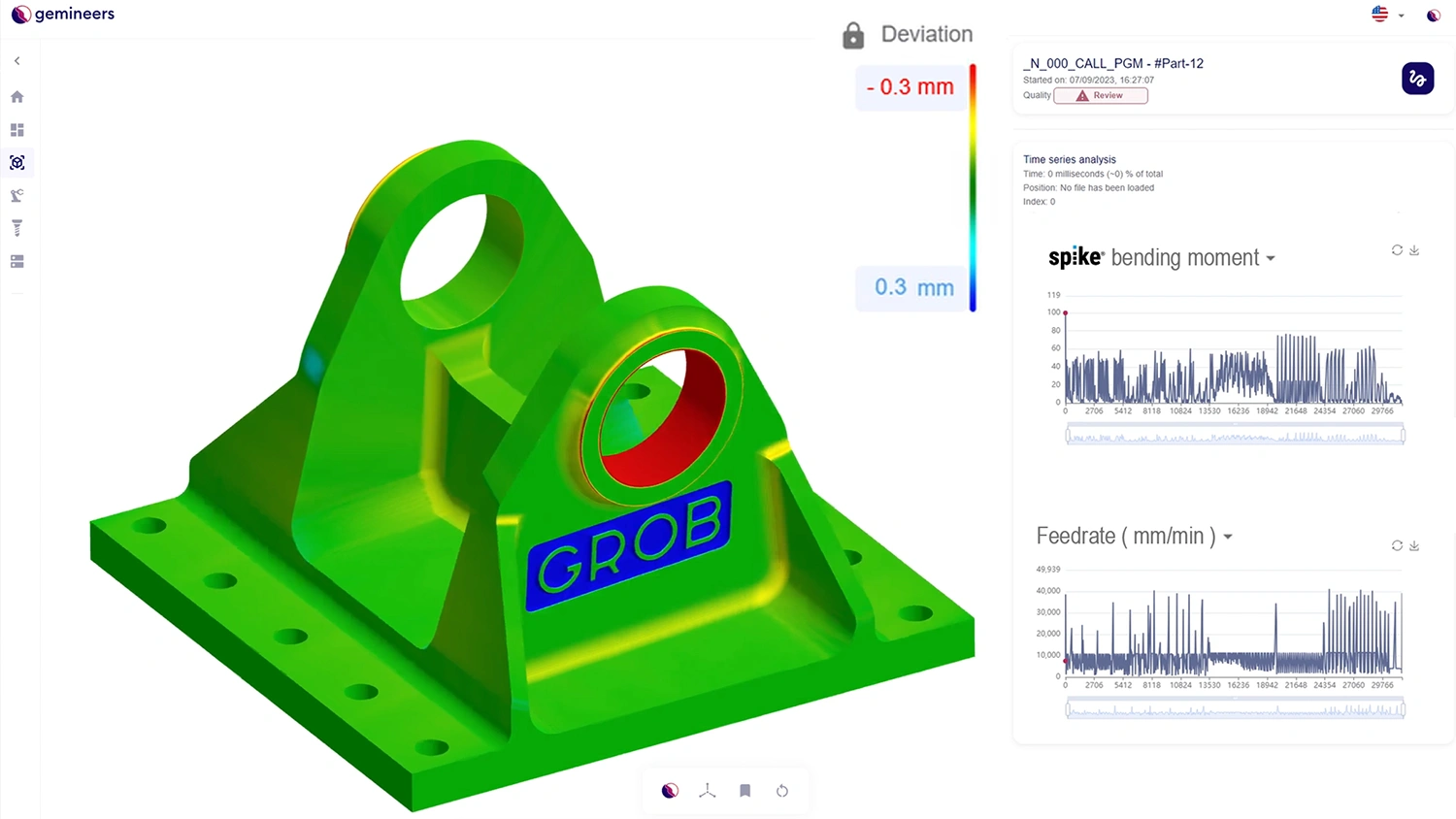

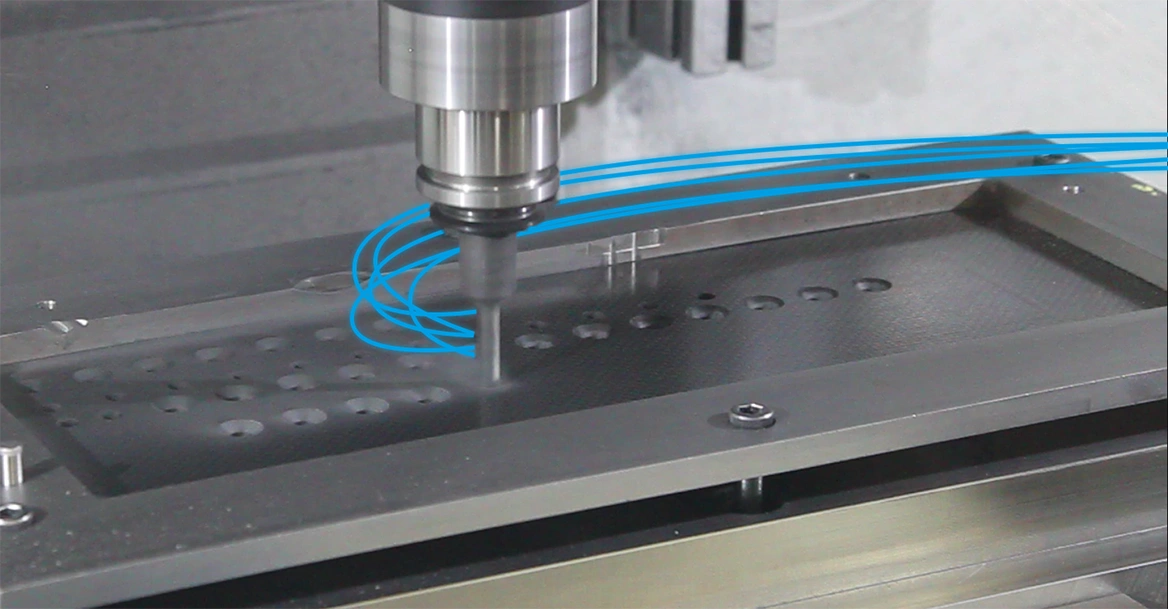

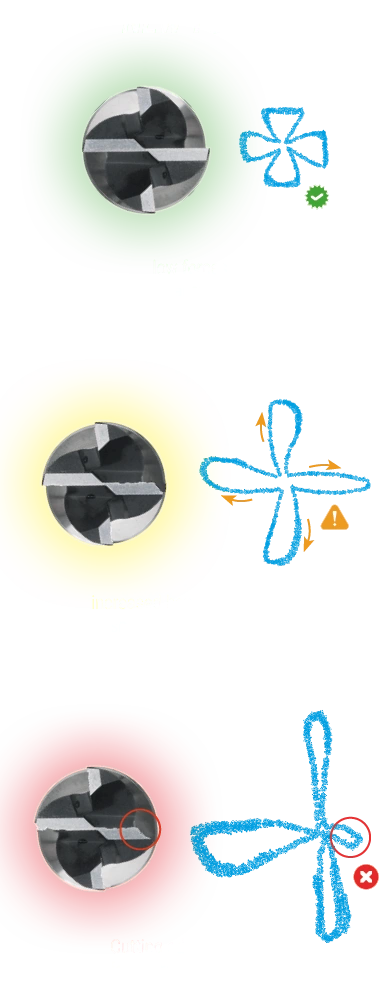

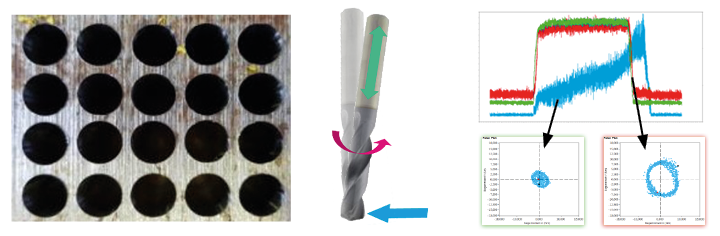

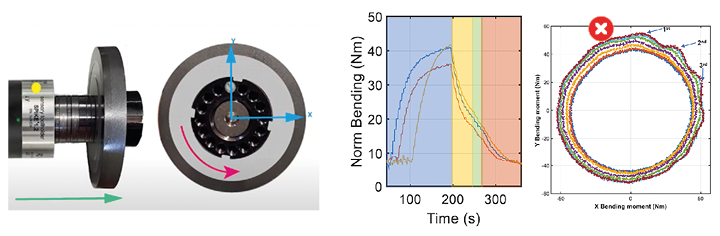

With our "single cutting edge detector" spike®, it is possible to measure the forces directly at the point of action and visualize them live during the process per individual cutting edge.

This provides permanent feedback on the condition of the cutting tool(-wear) and thus indirectly on the quality of the workpiece achieved (surface, shape & position tolerances, dimensional accuracy, etc.).

Measuring the forces enables the visualization of details others can‘t see. Our highest sensitivity sensors are especially relevant for high-quality production.

what you can do with spike®

Other applications

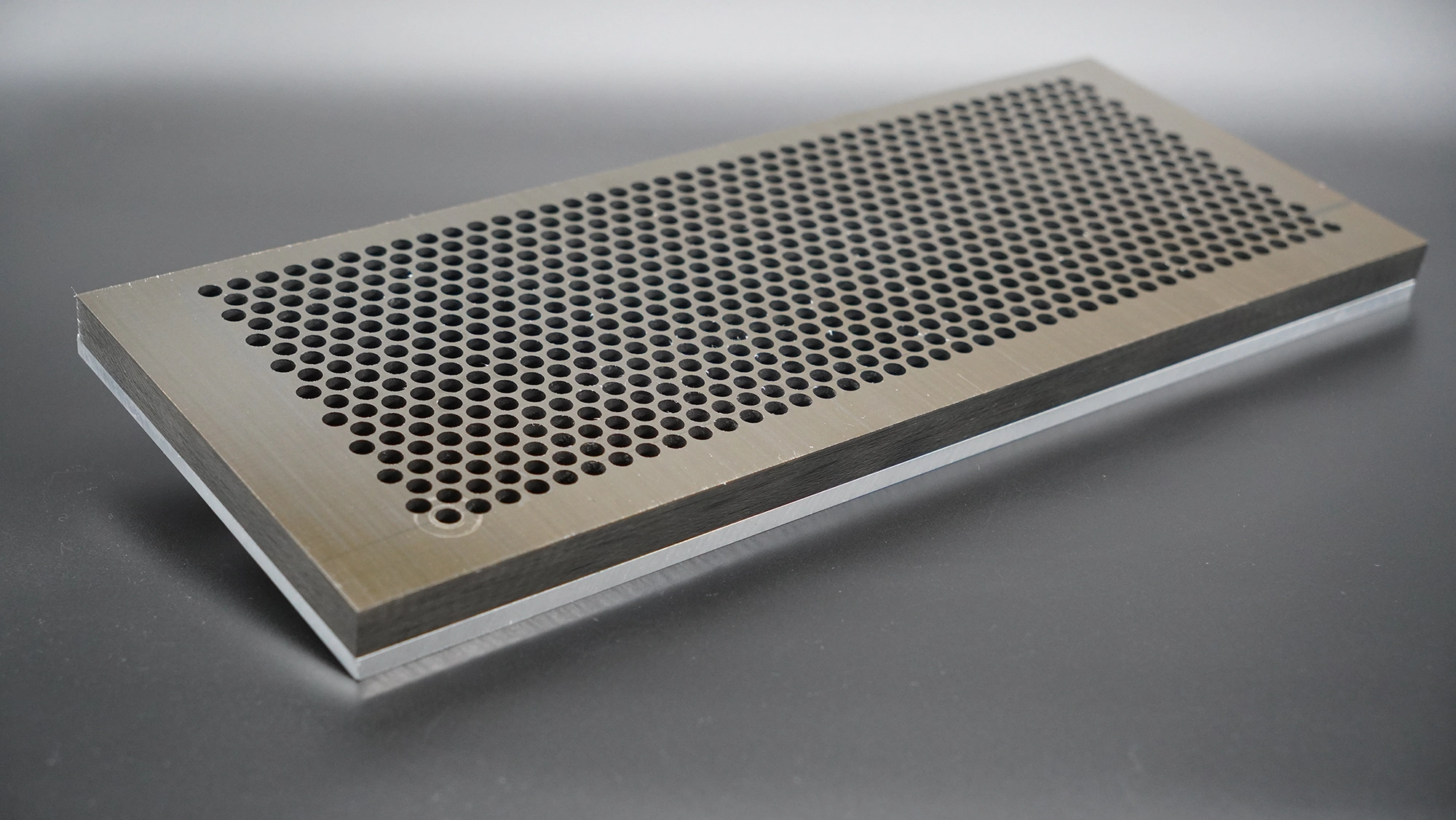

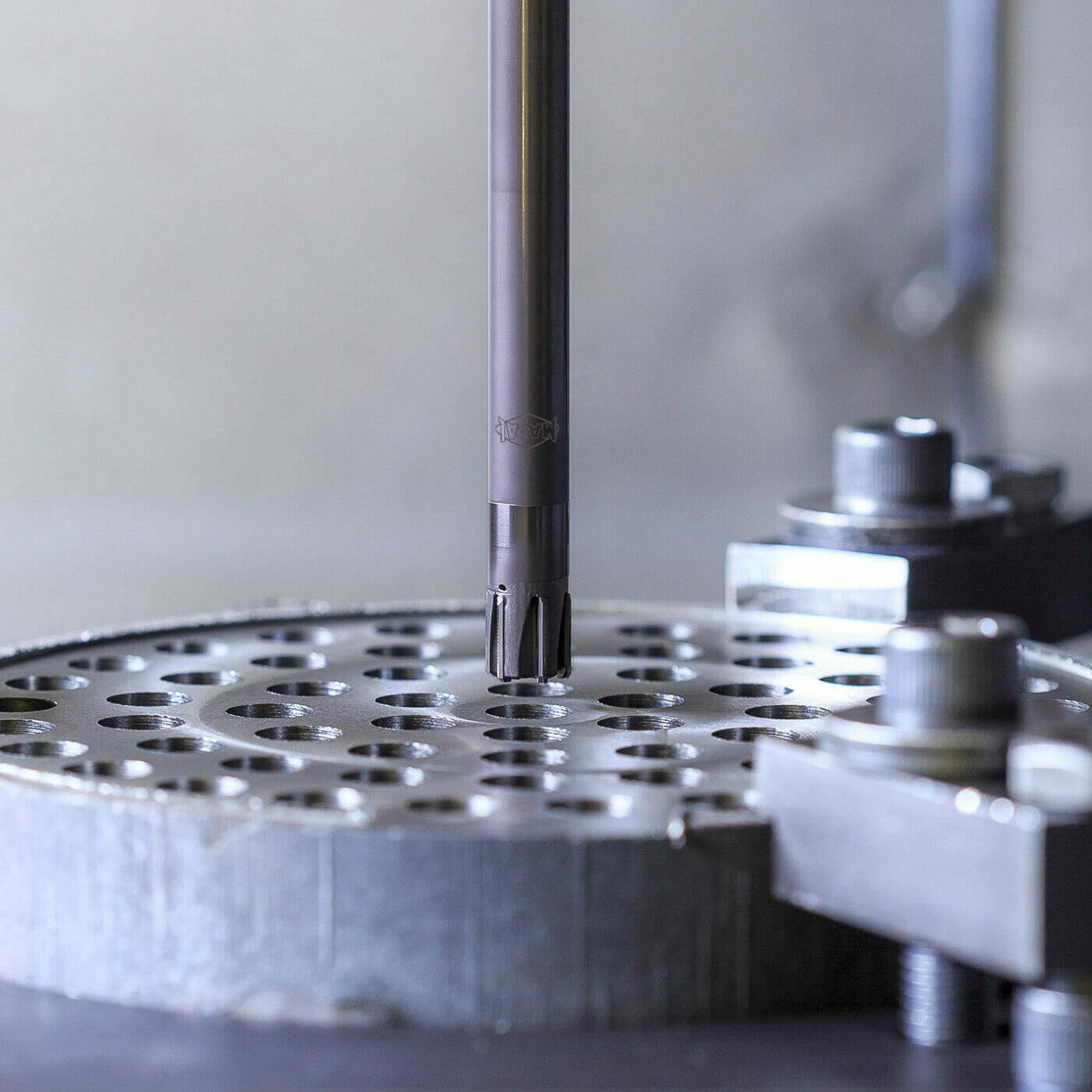

Drilling

run out / offset / wear / breakage

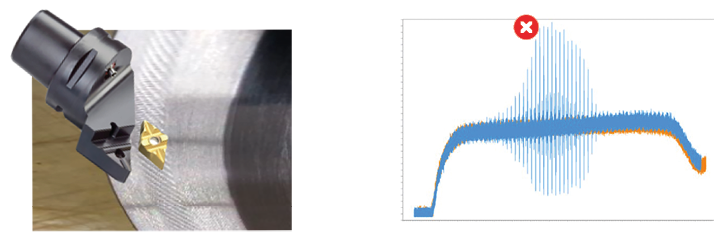

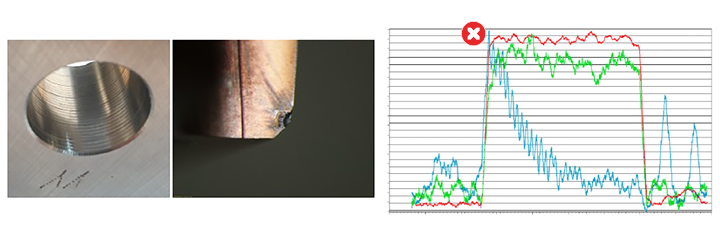

Turning

chatter / dimensions accuracy offset

Grinding

grinding burn / tool wear

Reaming

tool wear / cutting edge breakage

Your application is not included?

Start now with...

Flexible diagnosis set

- Can be used across machines

- Laboratory use

- Plug&Play < 1 minute

Retrofit series/pilot machine

- All Sensors

- Automated data recording

- Retrofittable < 2 days

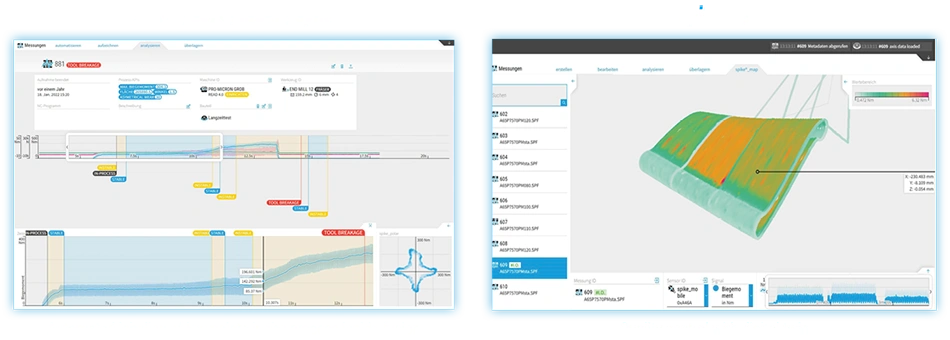

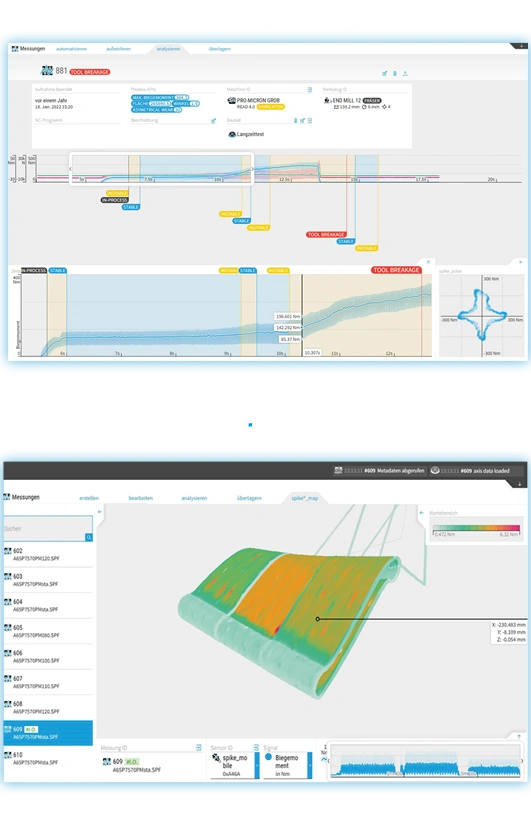

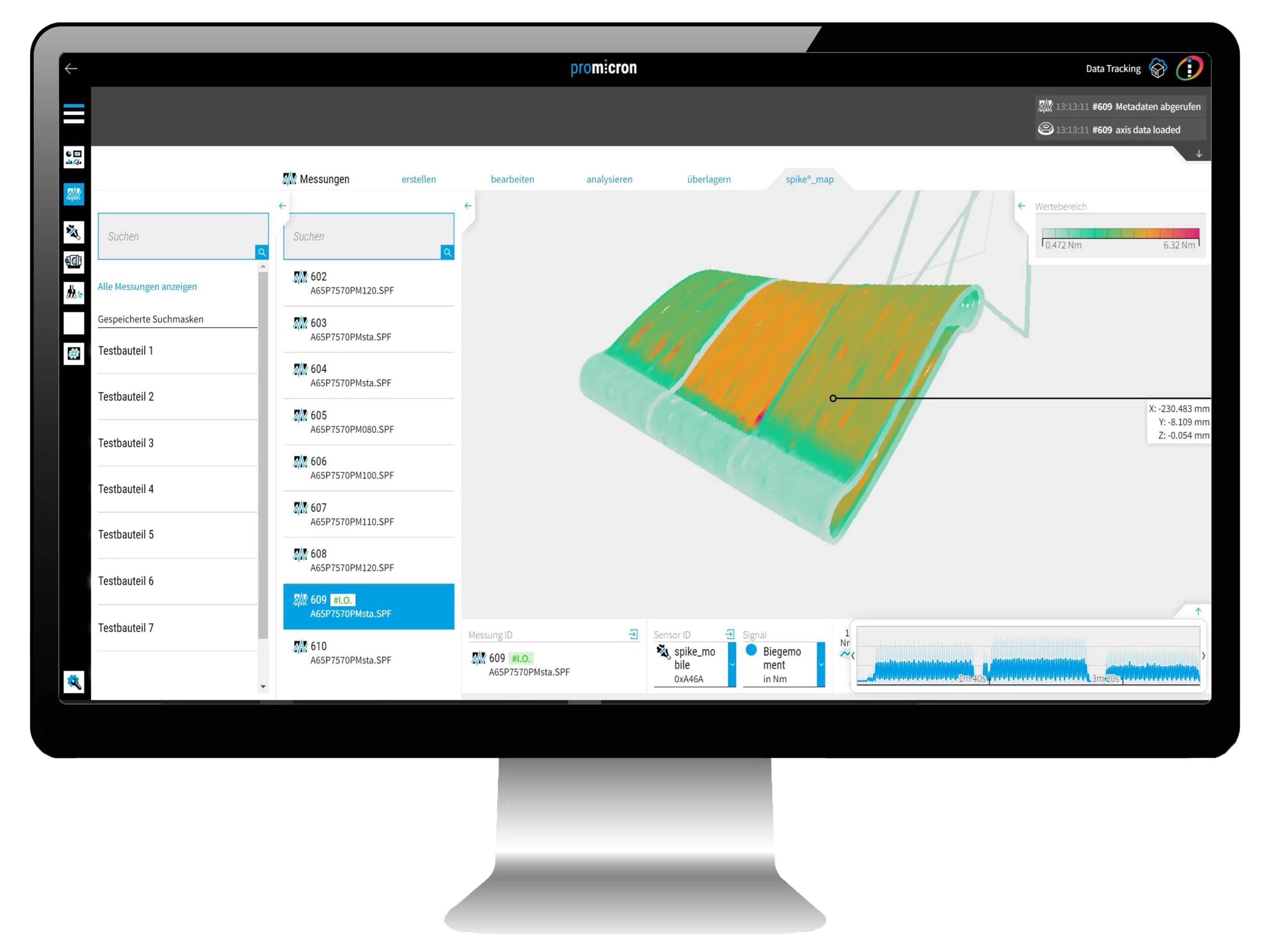

Analysis Software

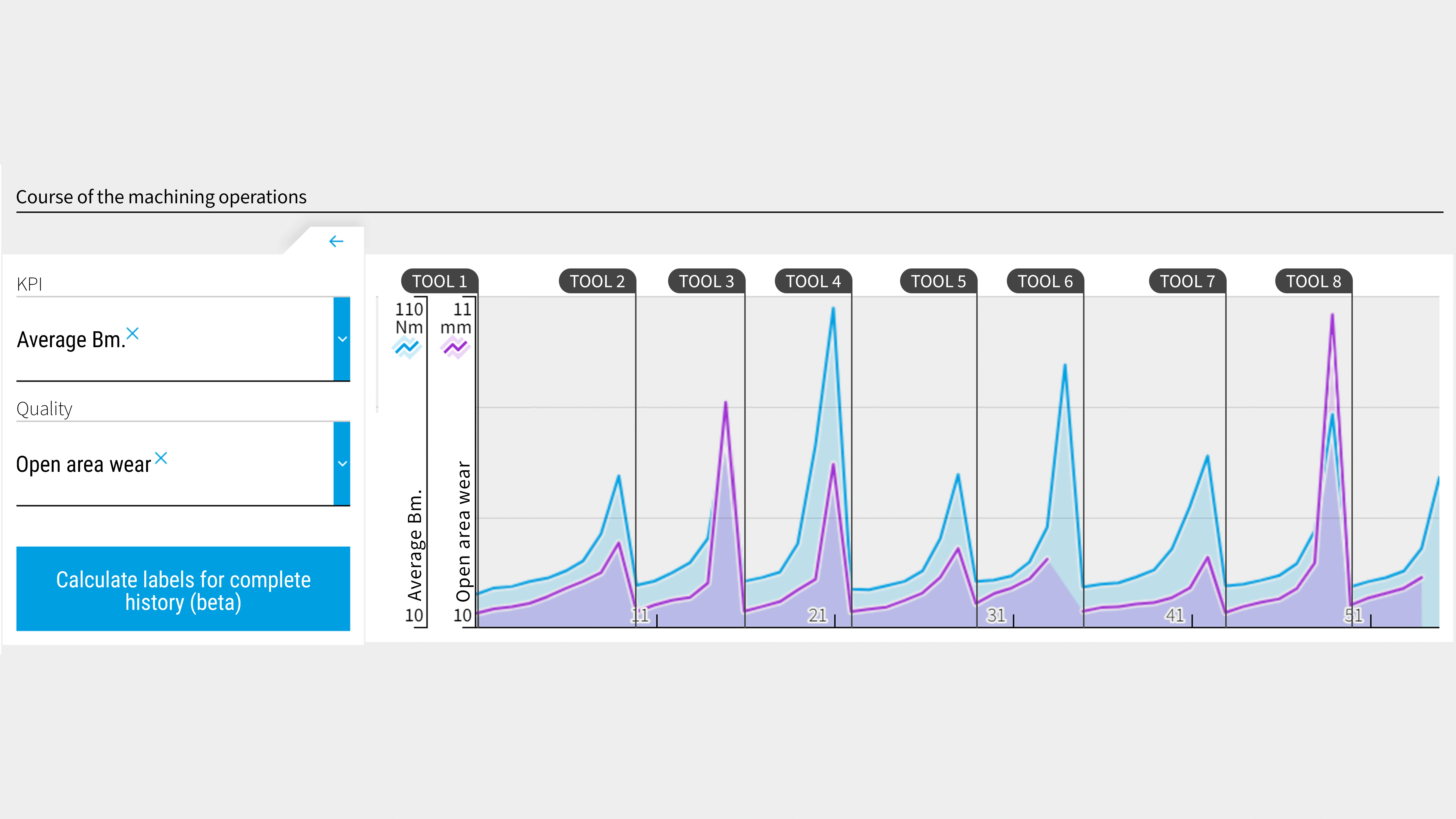

- Creation of measurement series for efficient long-term diagnosis

- Detailed analysis of single measurement files incl. spike®_polar visualization

- Compare & contrast measurement series/measurement data (single, trends, "spike_polar-stacking",....)

- Automated calculation of spike®_kpis (coming soon)

- Automated creation of reports (coming soon)

- Automatic calculation of correlation coefficients between measurement & quality data (coming soon)

- Use of database properties for efficient data evaluation

spike® Contact

PRODUCT INQUIRIES

Lennart Riehle

Head of Sales (Tool Control)

Tel.: +49 8341 9560 – 50

inquiry(a)pro-micron.de