Warum Temperaturmessung mit tip_e-motion im Rotor?

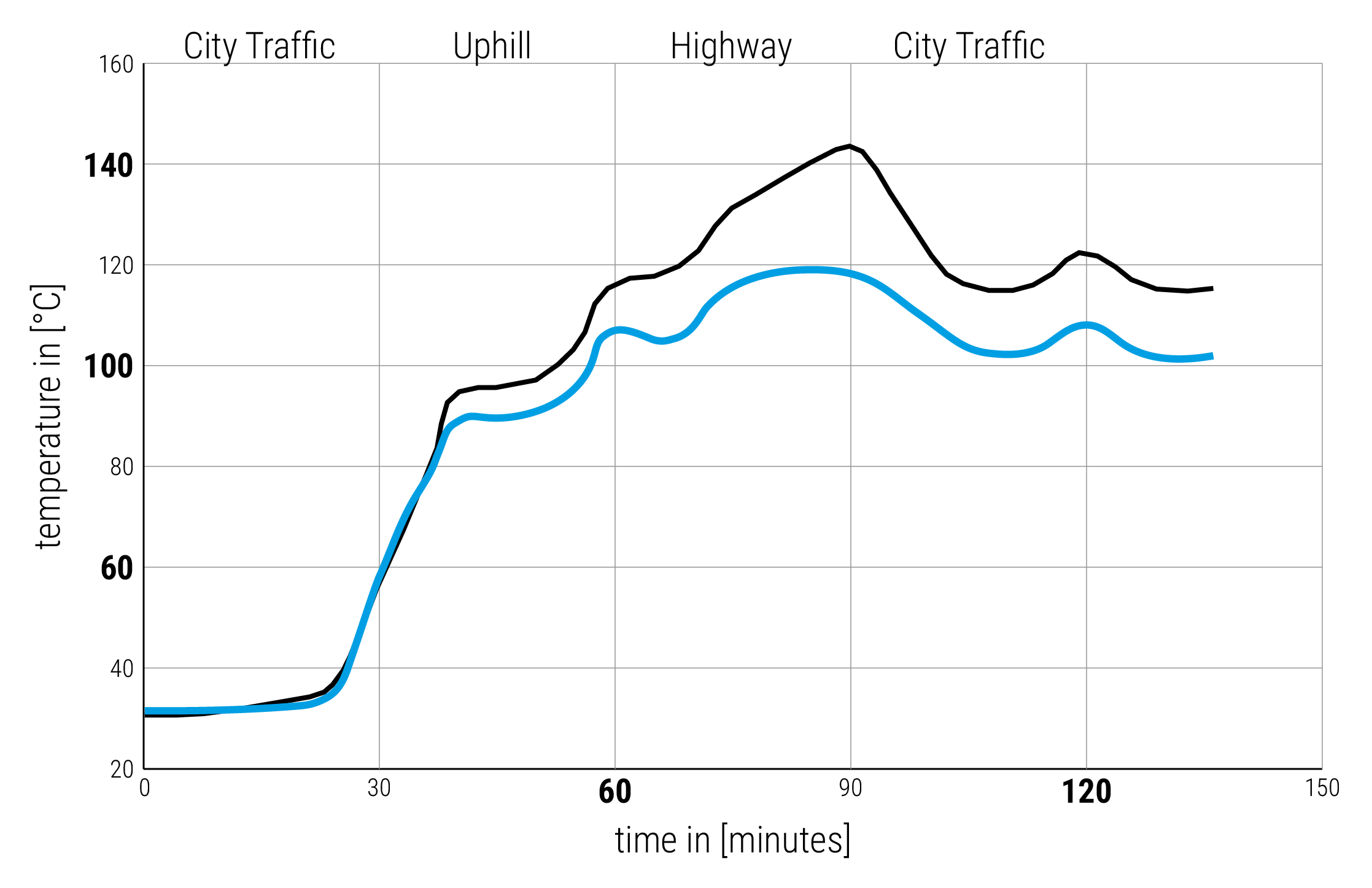

Rotor Temperatur: tip_e-motion vs. Simulation

Im Moment erfolgt die Berechnung der Rotortemperatur in Autos über ein physikalisches Modell aus der Statortemperatur. Diese Modelle beinhalten aber viele Annahmen und gemittelte Werte. Das individuelle Verhalten eines Motors in der realen Fahrsituation wird daher nur mit erheblichen Abweichungen berechnet.

Unsere Experimente mit tip_e-motion in unserem VW Caddy (E-Motor: Bosch SMG 180) zeigen: der Unterschied zwischen der errechneten und der tatsächlichen Temperatur der Magneten betrug stellenweise fast 25 Kelvin. Gerade in herausfordernden Situationen (z.B.: bergauf, im Stadtverkehr) steigt die Temperatur stark an.

GEMEINSAM MIT DER IAV GMBH HABEN WIR HERAUSGEFUNDEN, WAS ES BEDEUTET, DIE TEMPERATUR ZU KENNEN:

Weniger Kosten, gleiche Leistung

Mehr Leistung, gleiche Kosten

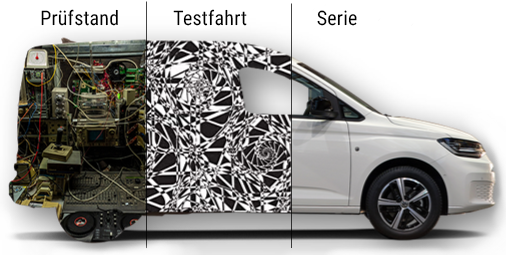

Was nur wir können: mit tip_e-motion vom Prüfstand auf die Straße

Aufgrund seiner Größe ist unser Sensorsystem vom Prüfstand über Testfahrzeug bis zum Serienfahrzeug integrierbar und zeichnet sich durch hohe Anpassungsfähigkeit an die Geometrie des Motors/verschiedene Sensorformen aus.

Im Vergleich zu telemetrischen Messsystemen:

- Keine Beeinflussung der Messung durch elektro-magnetische Störungen des Motors

- Keine Beeinflussung der Messung durch Kühlöl

- Keine Veränderung der Motor-Konstruktion zur Sensor-Integration nötig

Temperaturmessung am Rotor und Stator auf Prüfstand

Rotor-Temperaturmessung live auf der Straße

UNSERE KUNDEN WELTWEIT:

Tier-One-Lieferanten

![]()

Top 5 der

LKW-Hersteller weltweit

![]()

Top5 Motorrad- hersteller Europas

Top 10 der E-Auto-Hersteller weltweit

![]()

Flugzeugindustrie

Formel 1

![]()

Toolingindustrie

Zugindustrie

Tier-One-Lieferanten

![]()

Top 5 der

LKW-Hersteller weltweit

![]()

Formel 1

![]()

Flugzeugindustrie

Top 10 der E-Auto-Hersteller weltweit

![]()

Top5 Motorrad- hersteller Europas

Zugindustrie

Toolingindustrie

tip_e-motion Ansprechpartner

Produkt und Service

Hubertus von Zastrow

Geschäftsführer pro-micron

+49 8341 9560 - 50

tip_300(a)pro-micron.de