News from pro-micron

Stay informed and don´t miss any news

- Press Information

- trade fair reports

- Current Information

the topic of digitalization is making its way into the machining world. The virtual trade fair format DiMaP entered its second round from March 16 to 19. 16 companies and institutes from the entire machining value chain, from research institutes to machine builders, were present at the marketplace for digital machining in record numbers. Seminar…

Read MoreInternational online conference enters its second round – with 60 live slots from various partners. From March 16 to 19, experts along the machining value chain will present use cases on the topic of “digital machining”. As no physical trade shows can take place this half-year either, the successful DiMaP (Digital Machining Market Place) format…

Read MoreIn this interview, Managing Director Hubertus von Zastrow explains how he and his team want to use the innovation to drive the economy forward.

Read MoreSince the ground-breaking ceremony on November 3, 2019 for the new pro-micron headquarters, the anticipation of the whole pro-micron team has grown. Shortly before Christmas 2020, the new building was gradually moved into. Operations have been running successfully again since January 7th. The first wireless spit for Miele’s ovens left production in CW 02 of…

Read MoreDigitization, Industry 4.0, automation – no matter what you call it, no company can avoid dealing with the integration of intelligent and digitally networked systems. After all, the benefits that affect the entire value chain and improve process reliability, quality and efficiency are decisive in global competition. Digital interfaces on the grinding tool or integrated sensor technology in the tool holder or spindle nose offer easily implantable solutions for various grinding processes.

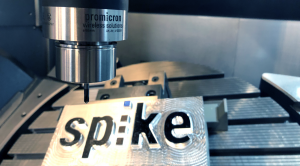

Read MoreEngine parts, metallic implants and many other components are machined from compact blocks of material by so-called metal-cutting manufacturing processes. Machine tools for metal-cutting manufacturing are among the most complex manufacturing systems, since dynamics must be combined with rigidity and, above all, precision in the sub-micrometer range. In particular, the interface between the machine and the respective cutting tool, the spindle, is subject to high mechanical loads. Until now, the systems have reached their limits because the analytical possibilities for deeper insights into the process and monitoring were not available.

Read MoreWireless sensor systems are the business field of pro-micron GmbH in Kaufbeuren. For example, for the documentation of processes in a machine and their control. Processes that could lead to even more effective results with the help of artificial intelligence (AI) – if data were no longer just collected, but could be evaluated by algorithms and provided with measures.

Read MoreThinking innovatively about a future together in the machining value chain. In the Directors´ Exchange on the 1st of July Ceratizit, PTW, Schaeffler, stama and pro-micron talked about artificial intelligence in the machining industry.

Read More