Single Cutting edge detector spike®

for TOOL FAILURE POINT PREDICTION

Ihr Partner auf dem Weg zur autonomen Zerspanung

Mit seiner spike® Technologie bietet pro-micron seinen Kunden einen Weg zur autonomen Zerspanung.

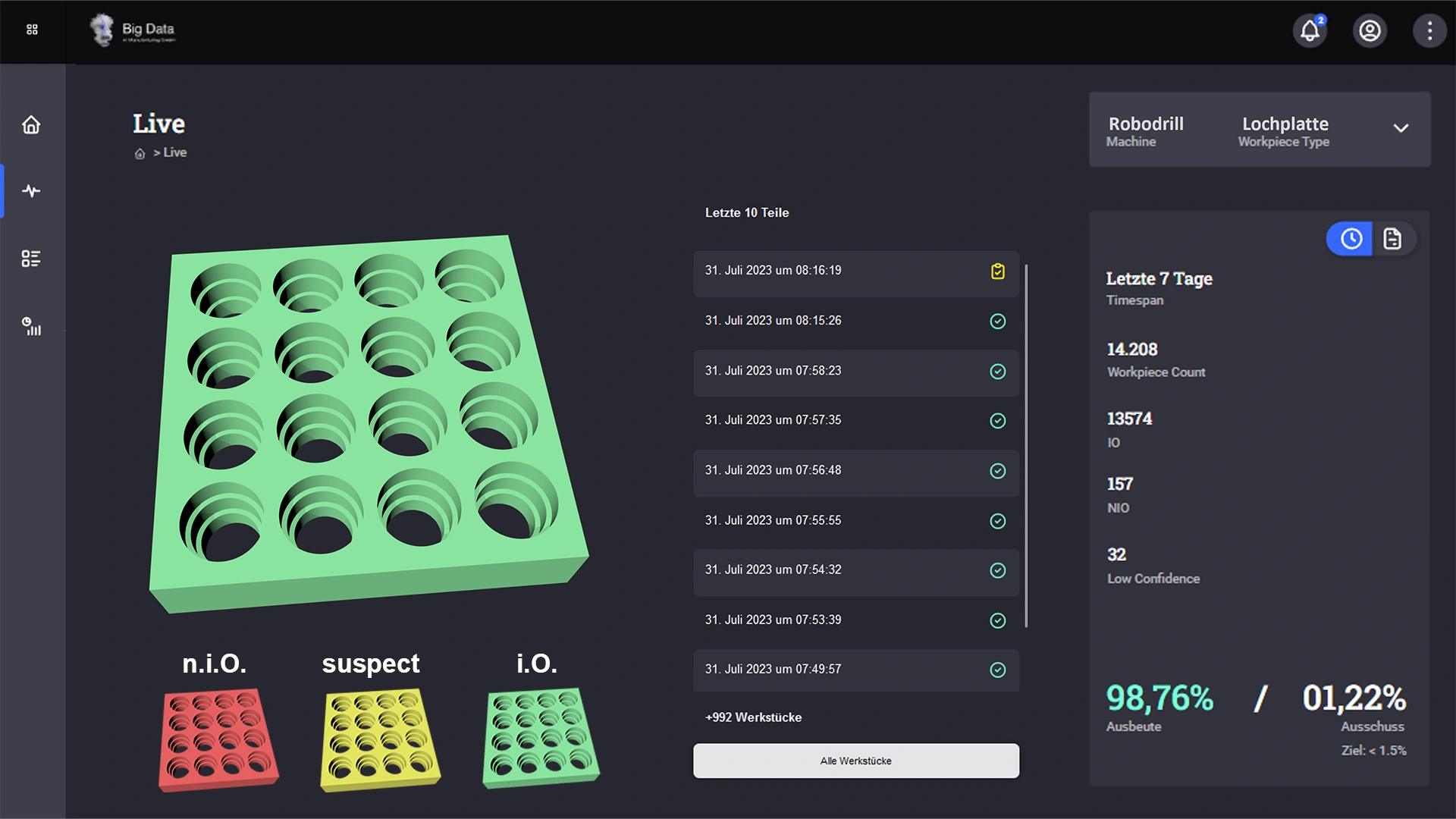

Intelligente Sensoren mit hochsensitiven, einzigartigen Signalen sowie fortschrittliche Software-Tools, die Prozess- und Maschinendaten sammeln, synchronisieren und sortieren, ermöglichen unseren Kunden nicht nur die Analyse und Überwachung ihrer (Serien-)Produktion, sondern auch die Vorhersage von Qualitätsergebnissen in Echtzeit unter Verwendung von KI-Algorithmen.

Starke Partnerschaften von Unternehmen entlang der Wertschöpfungskette machen dies möglich.

Unsere Technologie

Sensoren für Prozessdaten Tracking

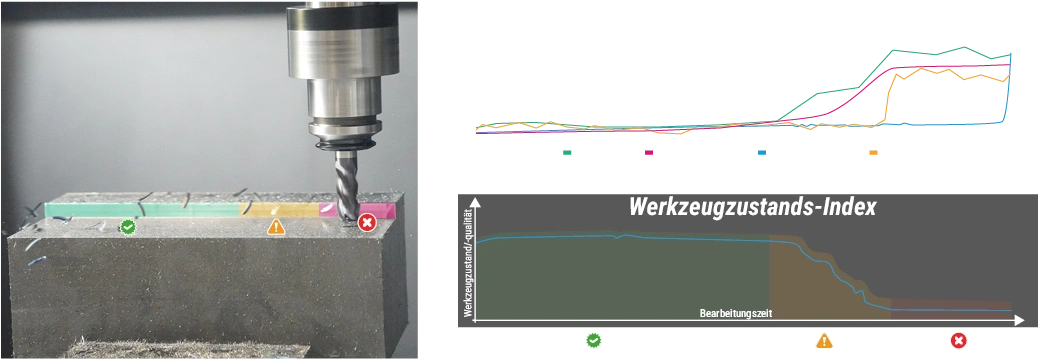

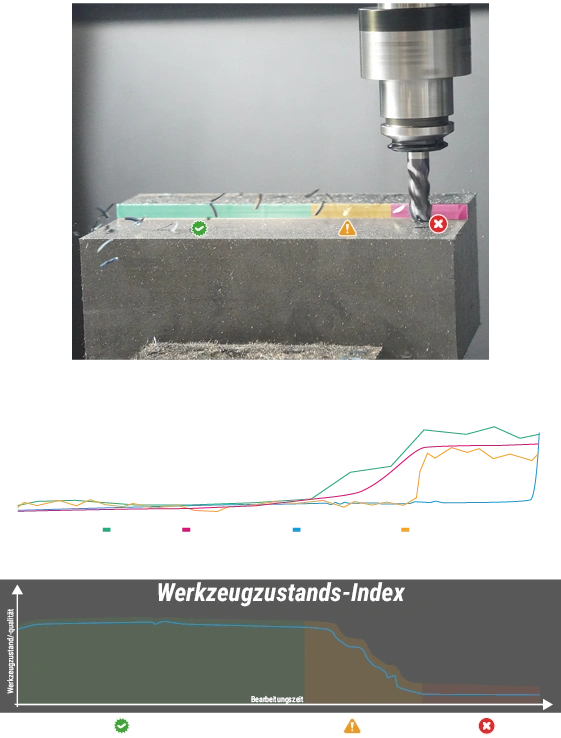

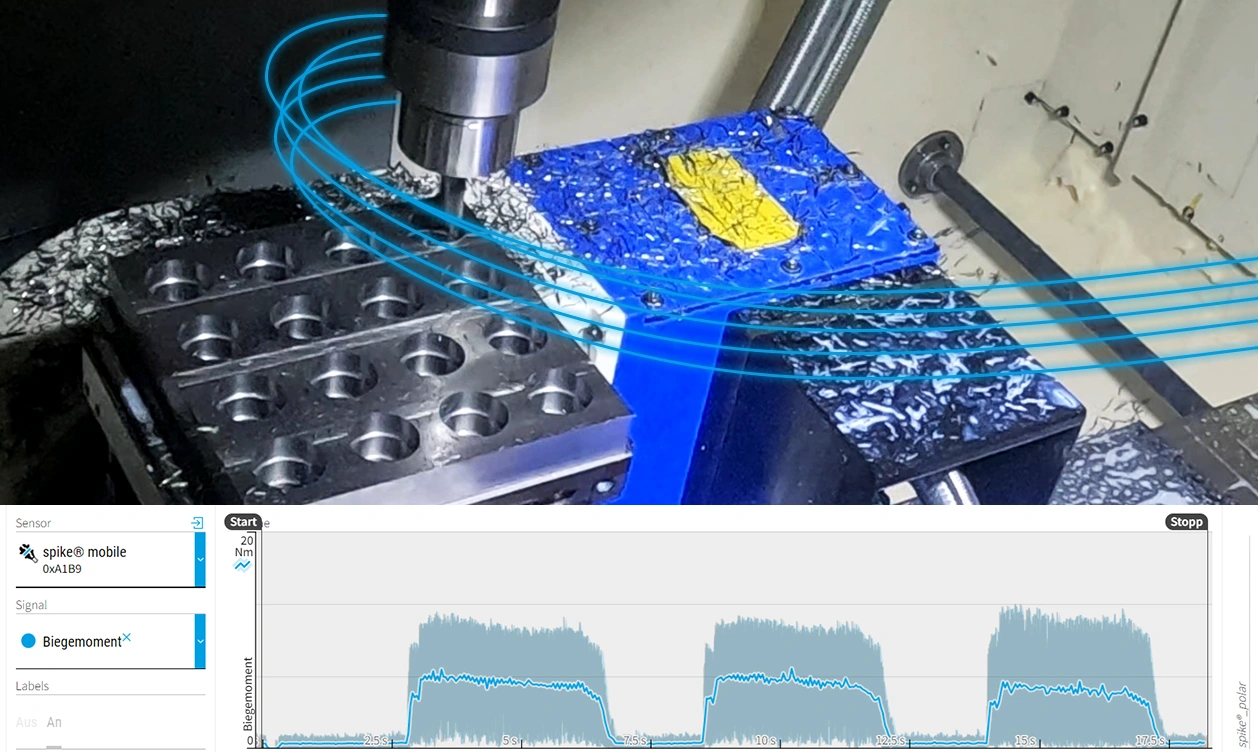

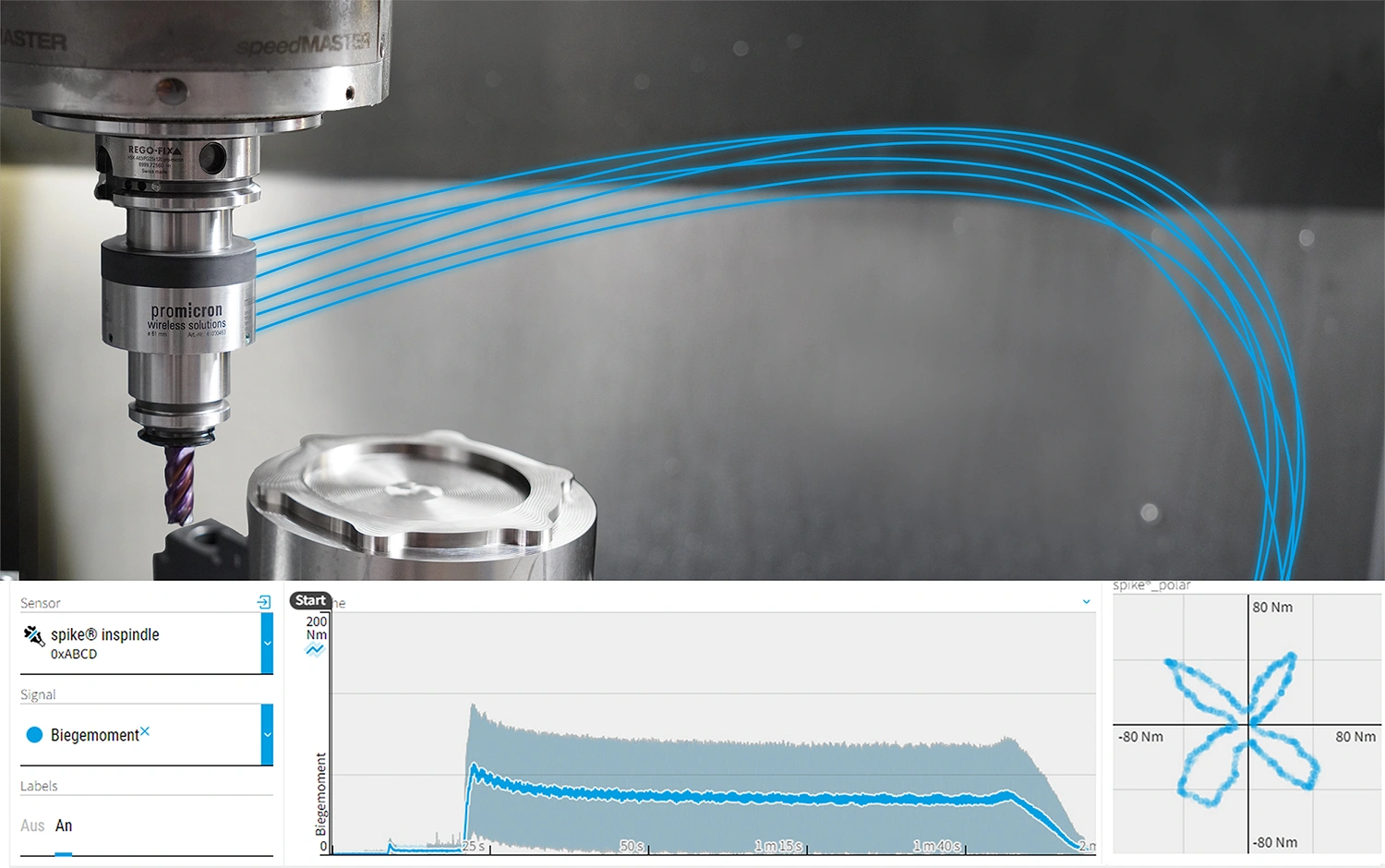

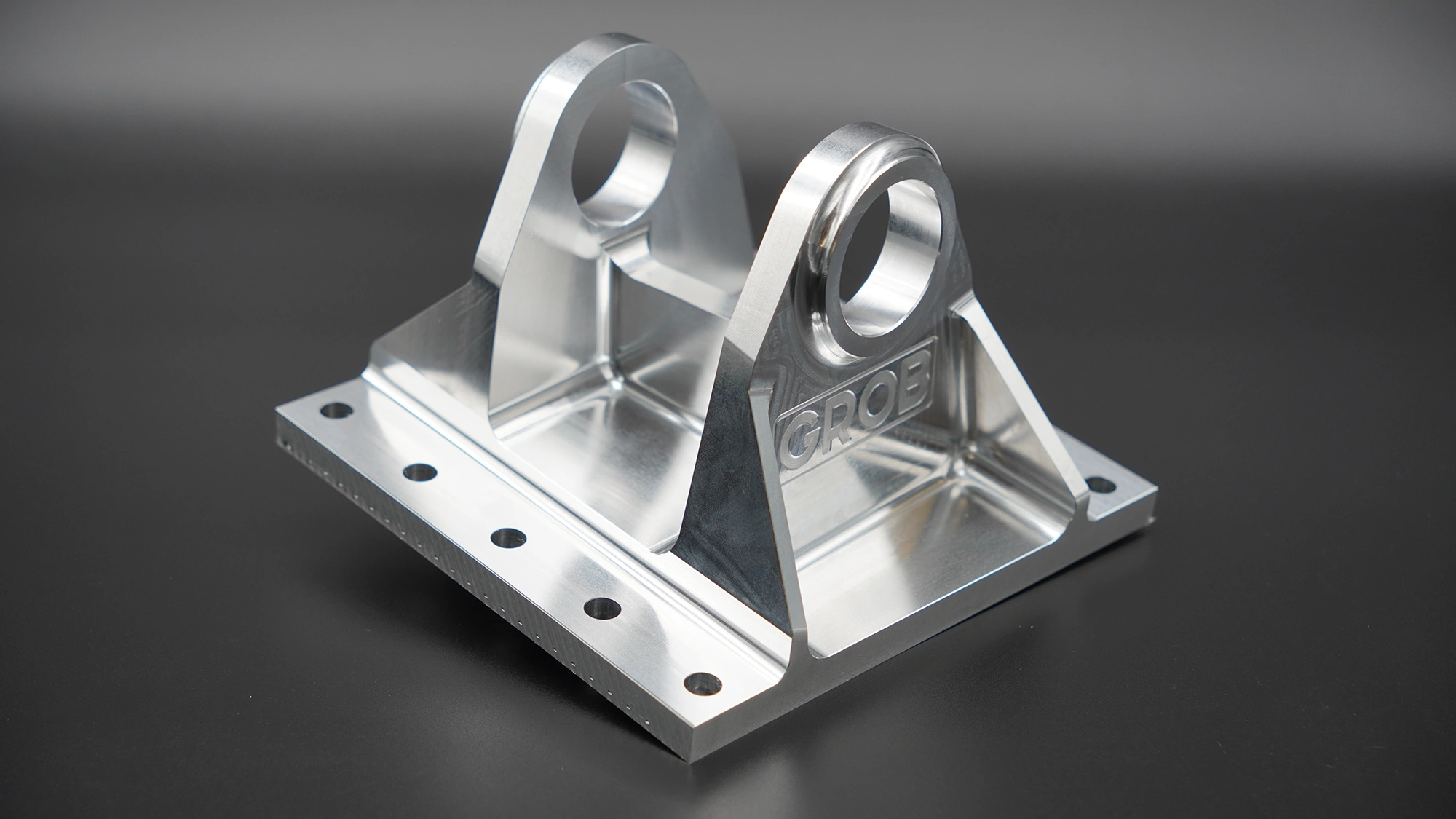

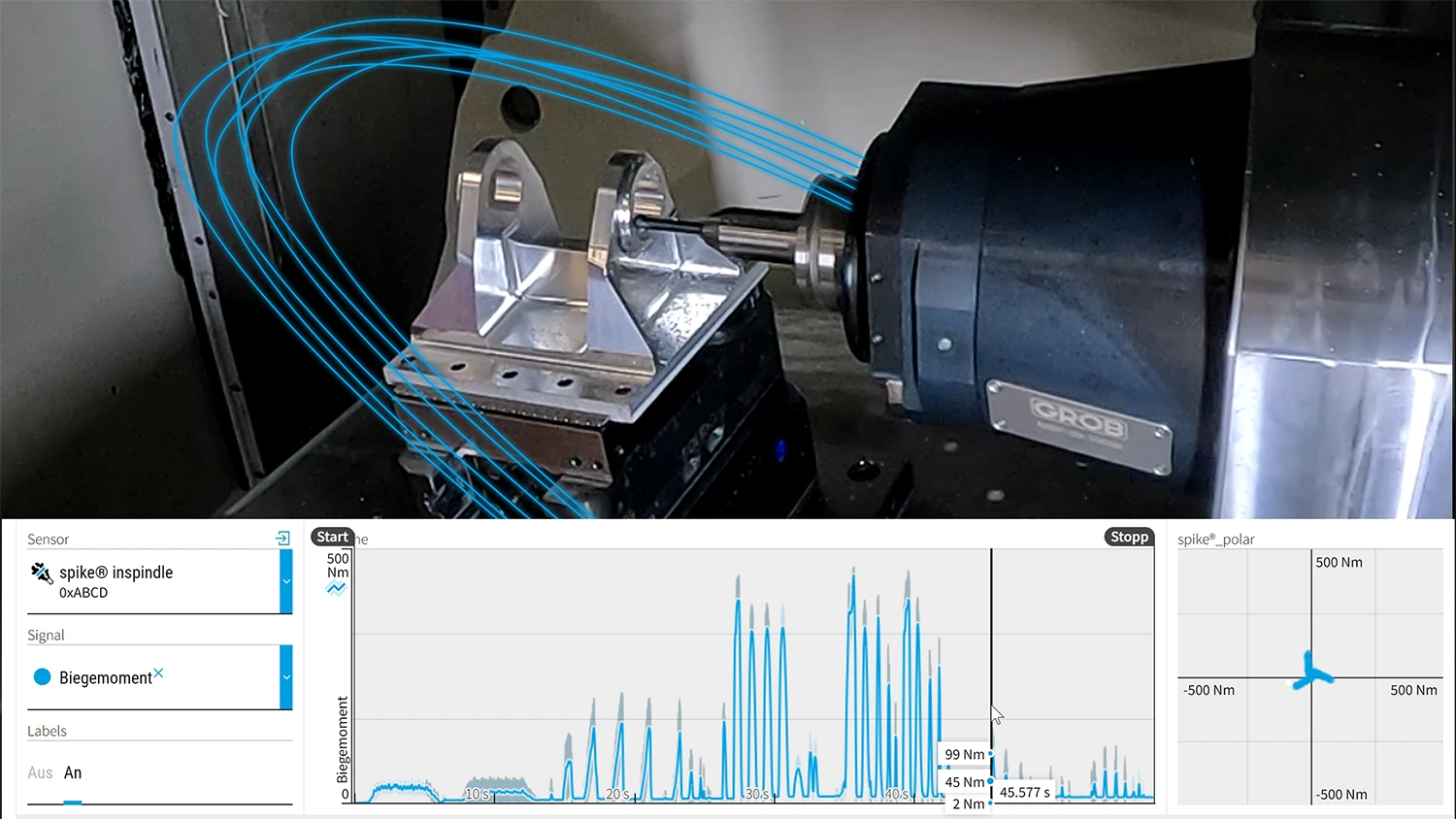

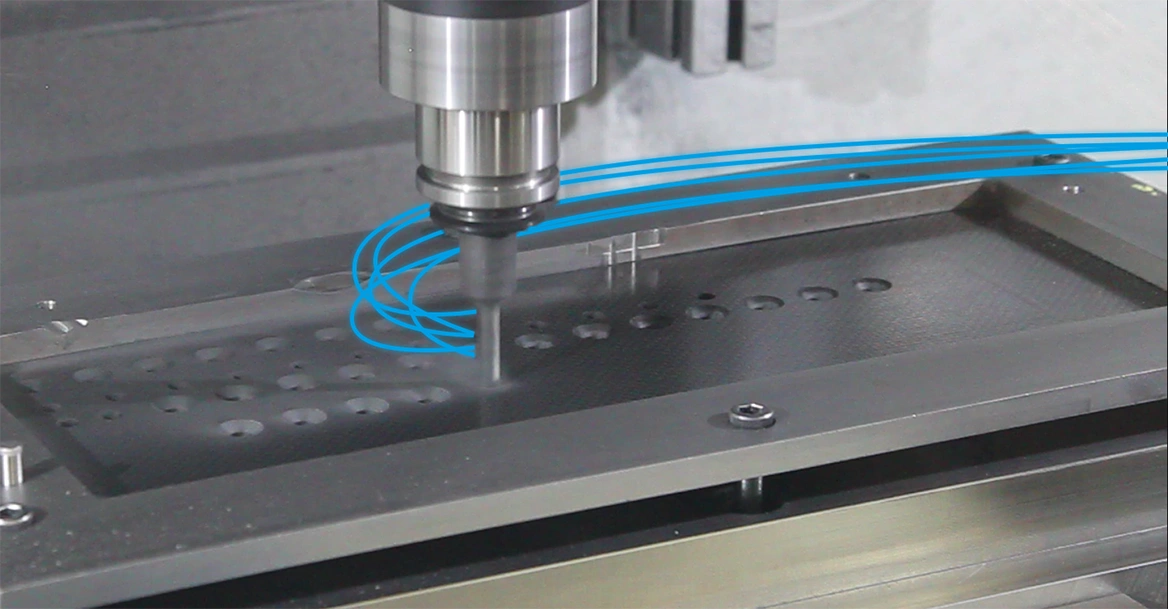

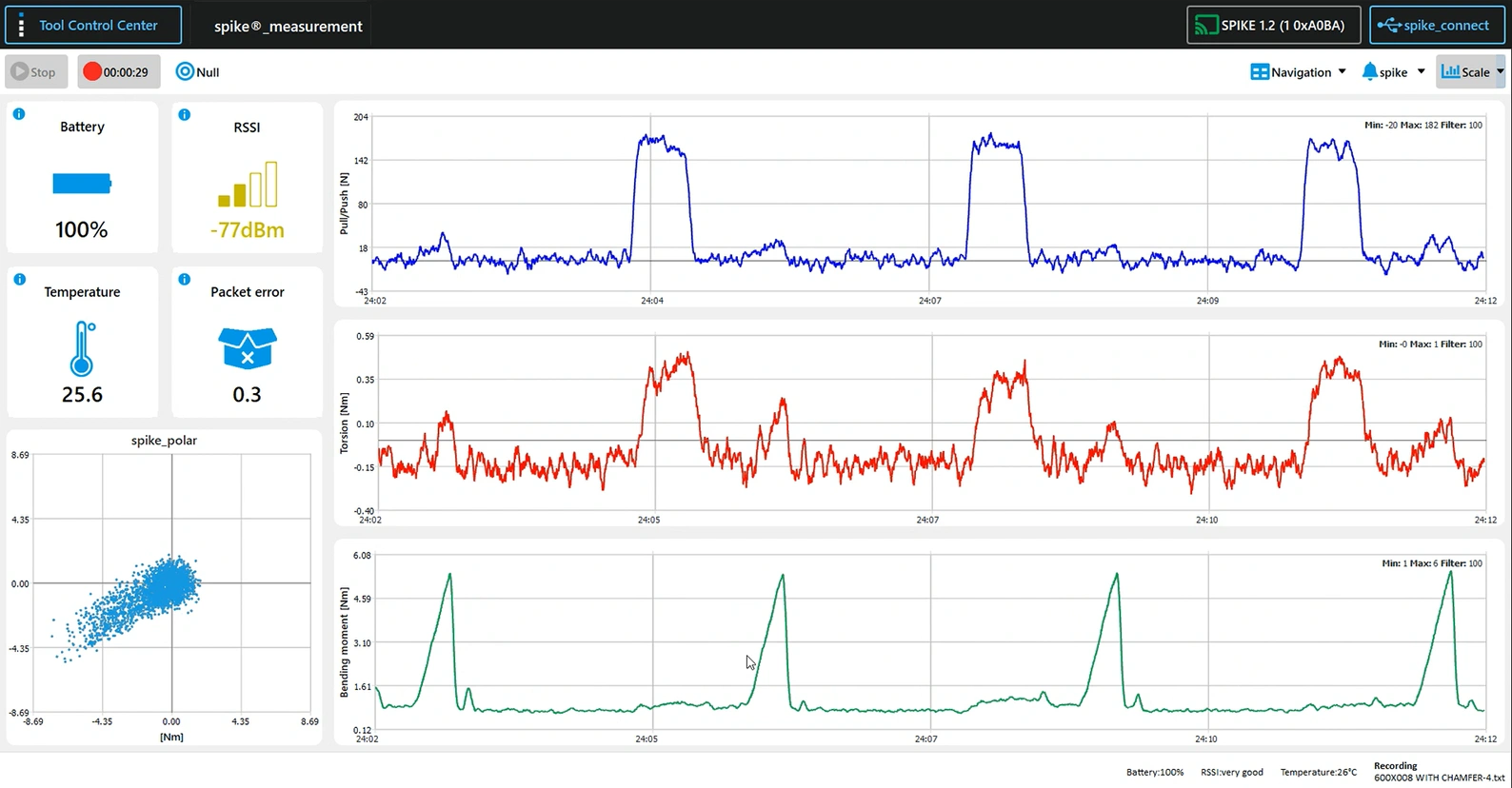

Mit unserem "single cutting edge detector" spike® ist es möglich, die Kräfte direkt am Wirkort zu messen und live während der Bearbeitung jede einzelne Schneide zu visualisieren.

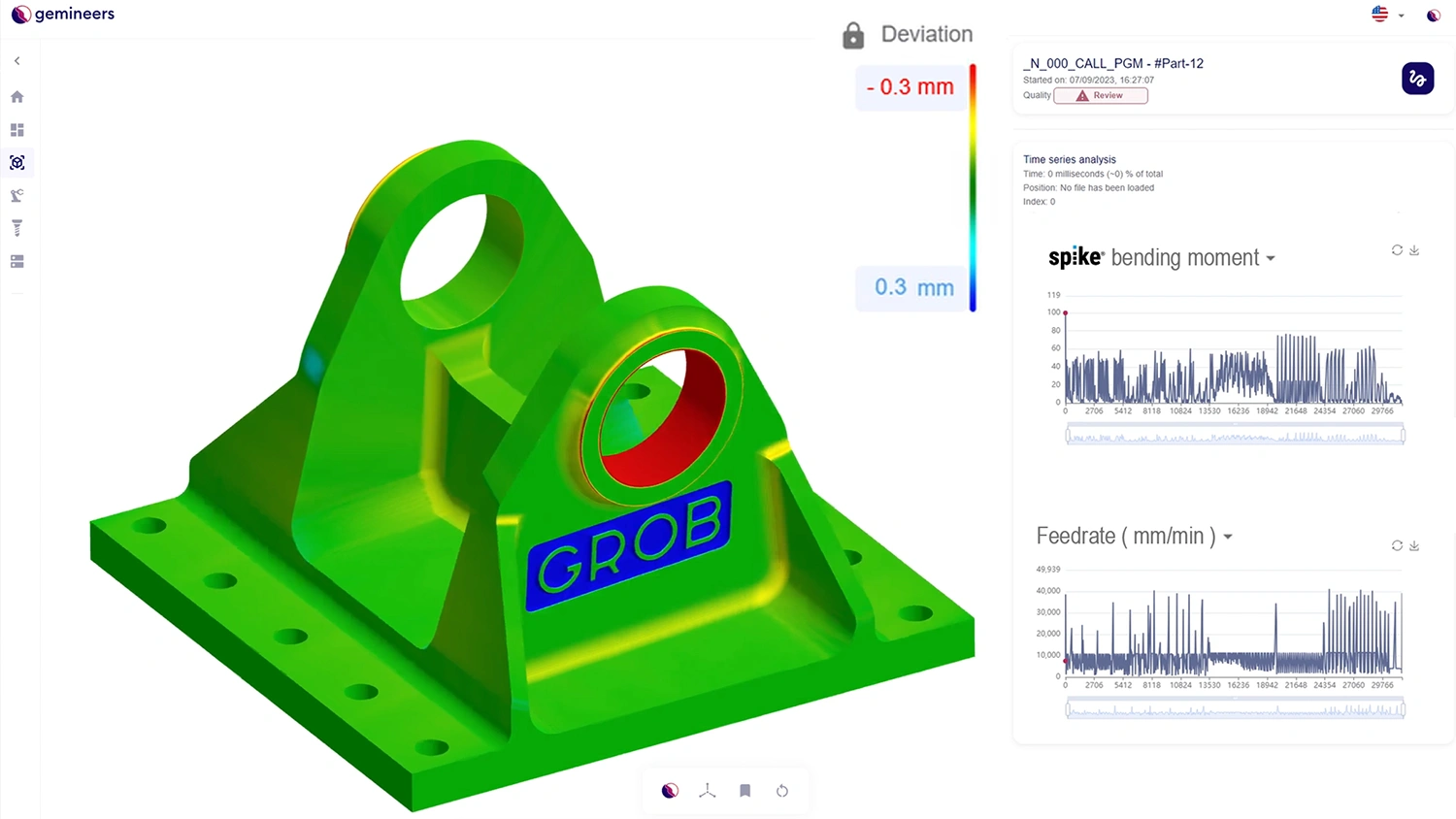

Durch kontinuierliches Feedback zum Zustand des Werkzeugs lassen sich während des Prozesses Prognosen über die Qualität des Werkstücks (Oberflächen-, Form- und Lagetoleranzen, Maßhaltigkeit usw.) erstellen.

Die exakte Zerspankraftmessung ermöglicht die Visualisierung von üblicherweise verborgenen Details. Unsere hochsensiblen Sensoren empfehlen sich besonders für Prozesse mit hohem Qualitätsanspruch.

spike® use cases

Weitere Einsatzmöglichkeiten

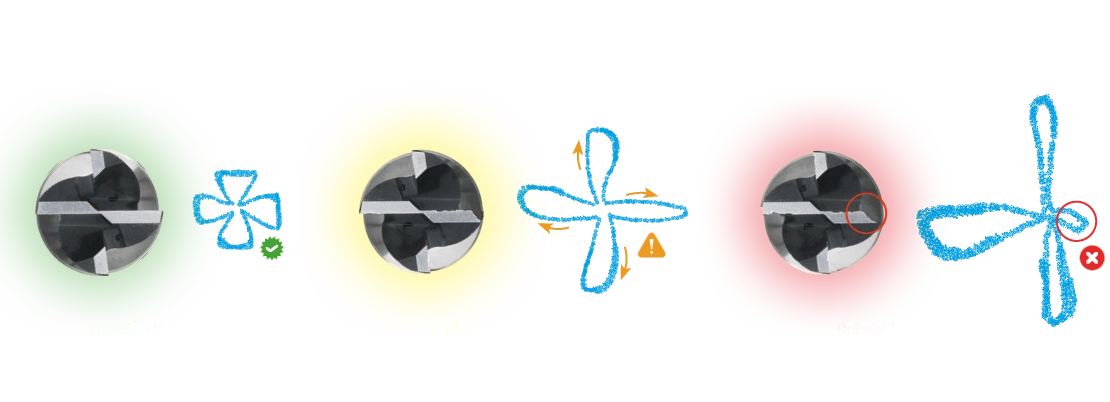

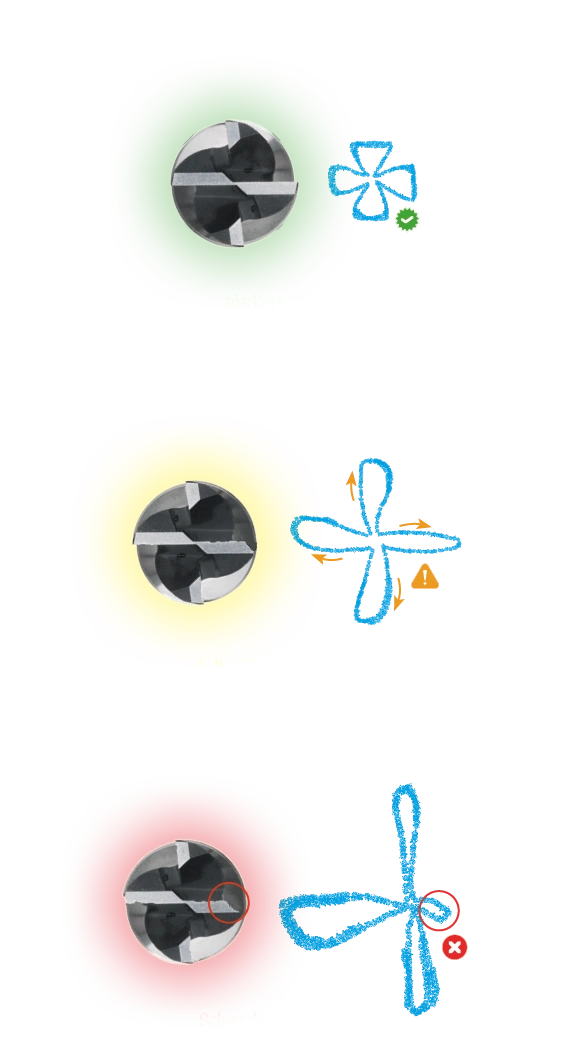

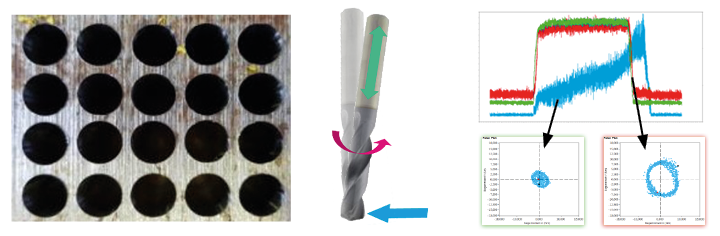

Bohren

Verlaufen / Versatz / Verschleiß / Bruch

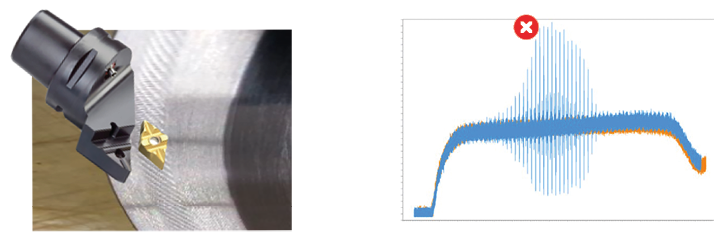

Drehen

Rattern / Aufmaßabweichung

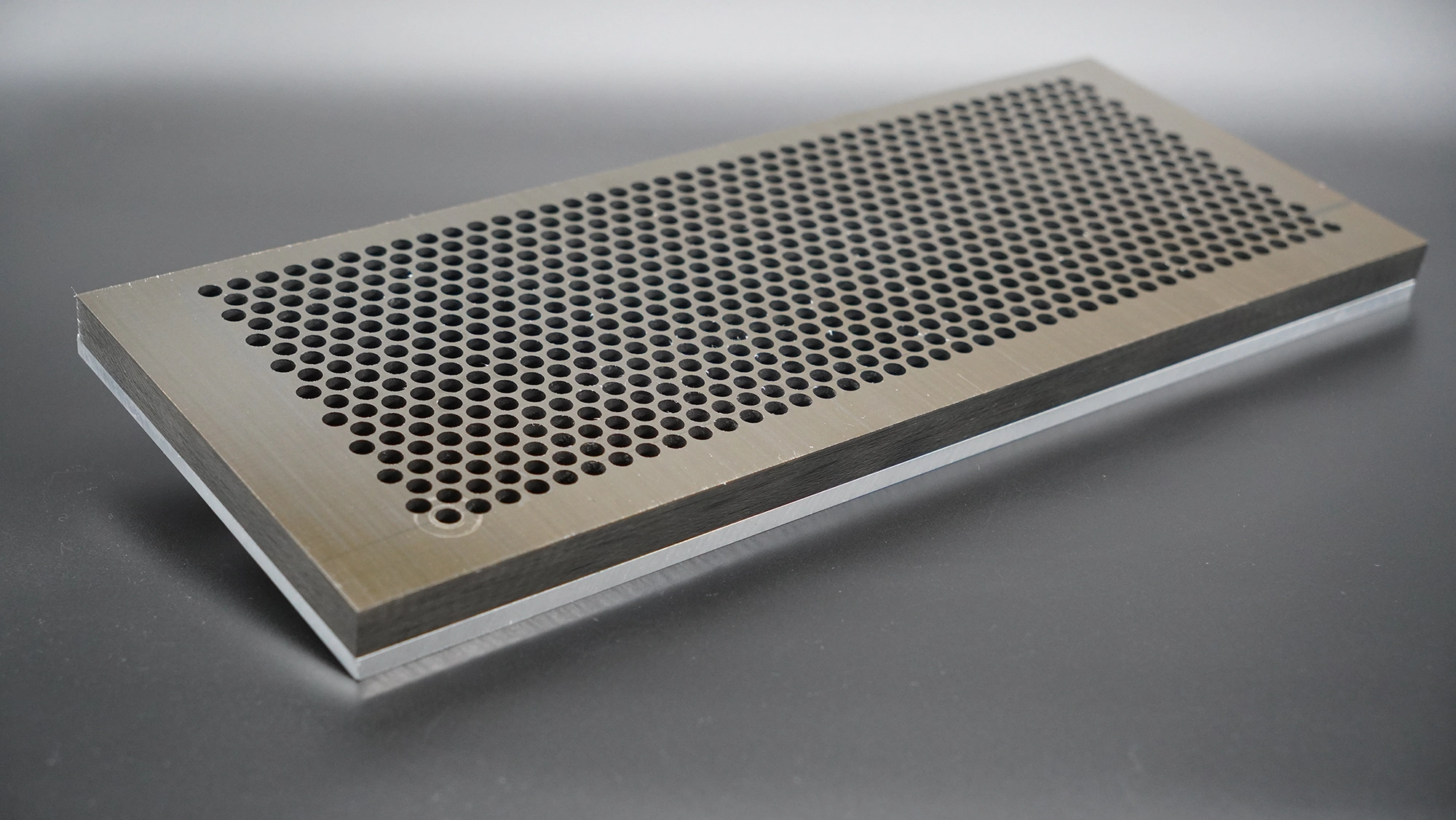

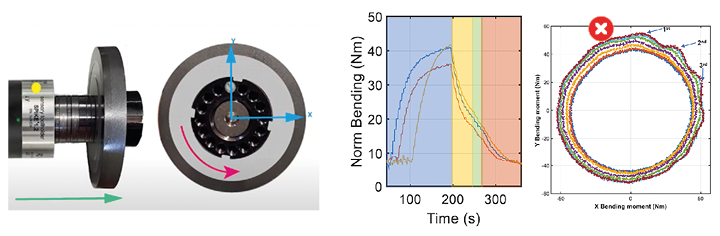

Schleifen

Verschleiß / Schleifbrand

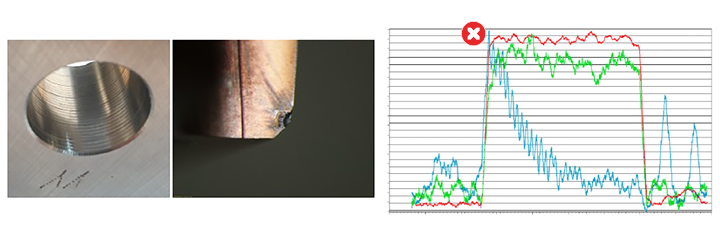

Reiben

Verschleiß / Schneidenausbruch

Ihre Anwendung ist nicht dabei?

Jetzt loslegen...

Flexibles Diagnose-Set

- Einsatz von Maschine zu Maschine

- Einsatz im Labor

- Plug&Play < 1 Minute

Serien-/Pilotmaschine nachrüsten

- Alle Sensoren

- Automatisierte Datenaufzeichnung

- Nachrüstbar in < 2 Tagen

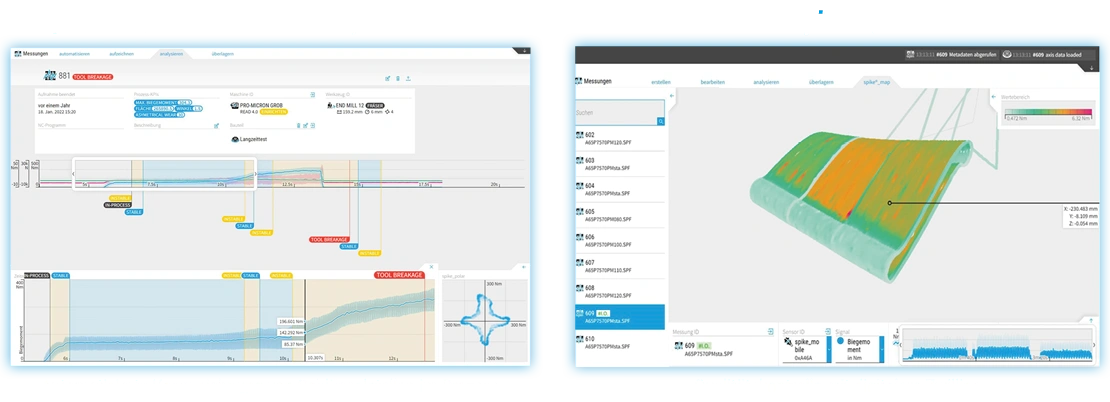

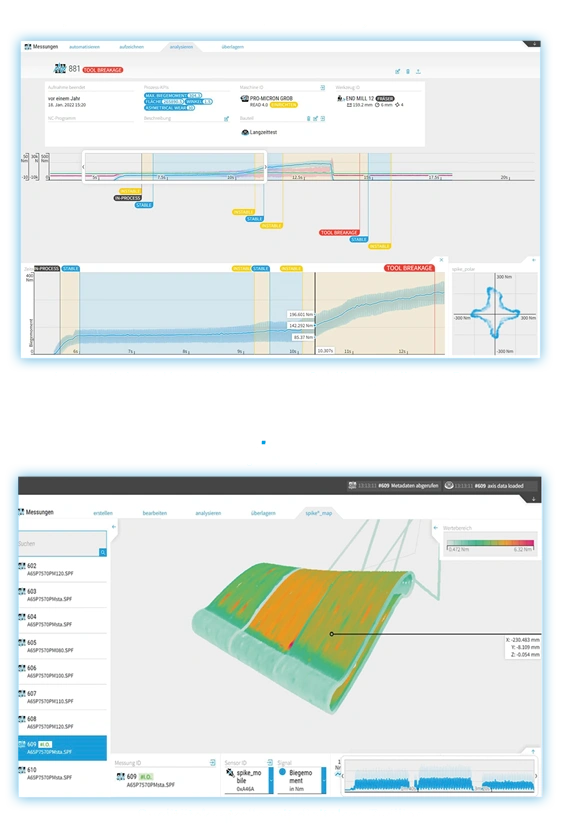

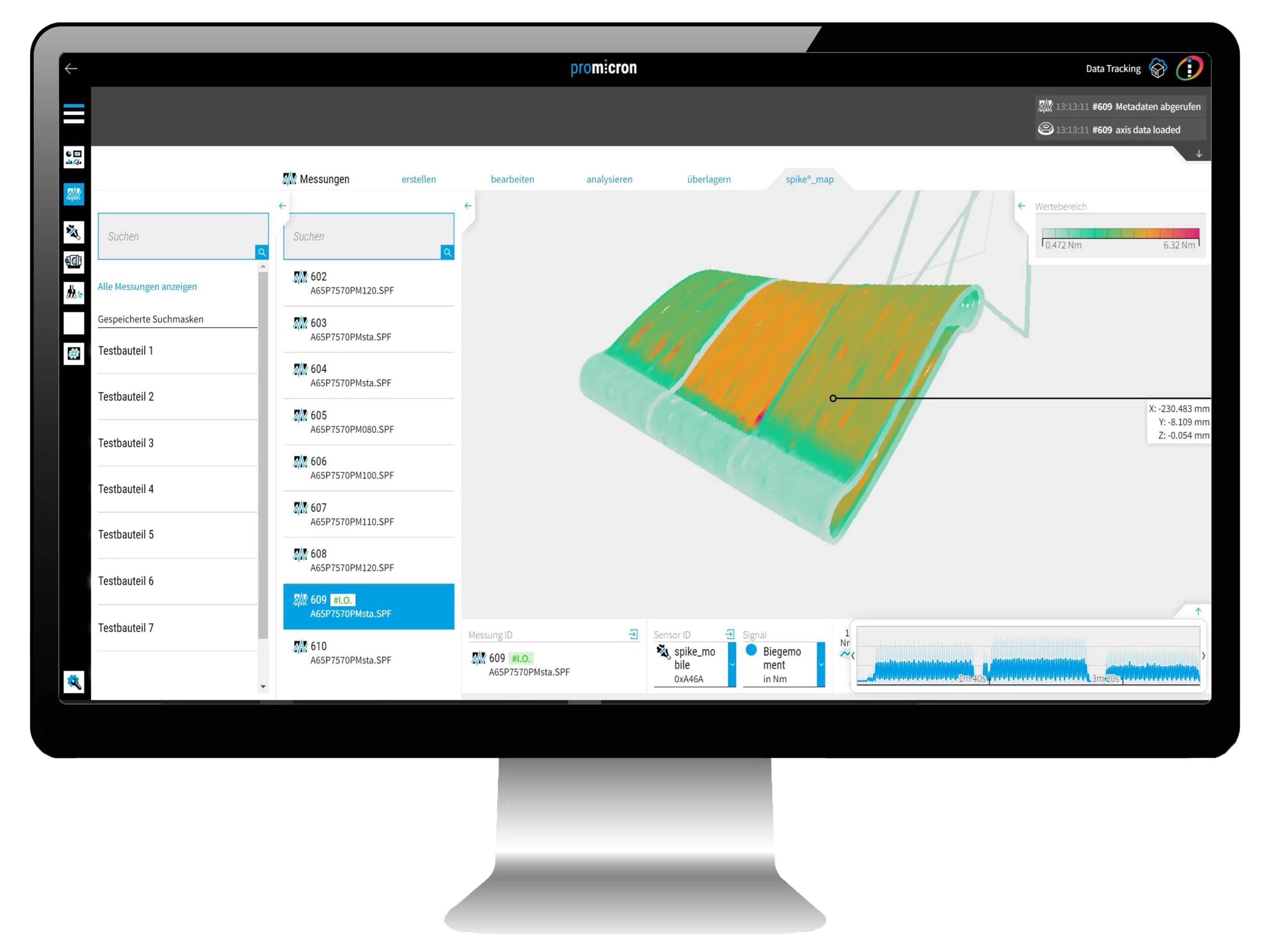

Analyse Software

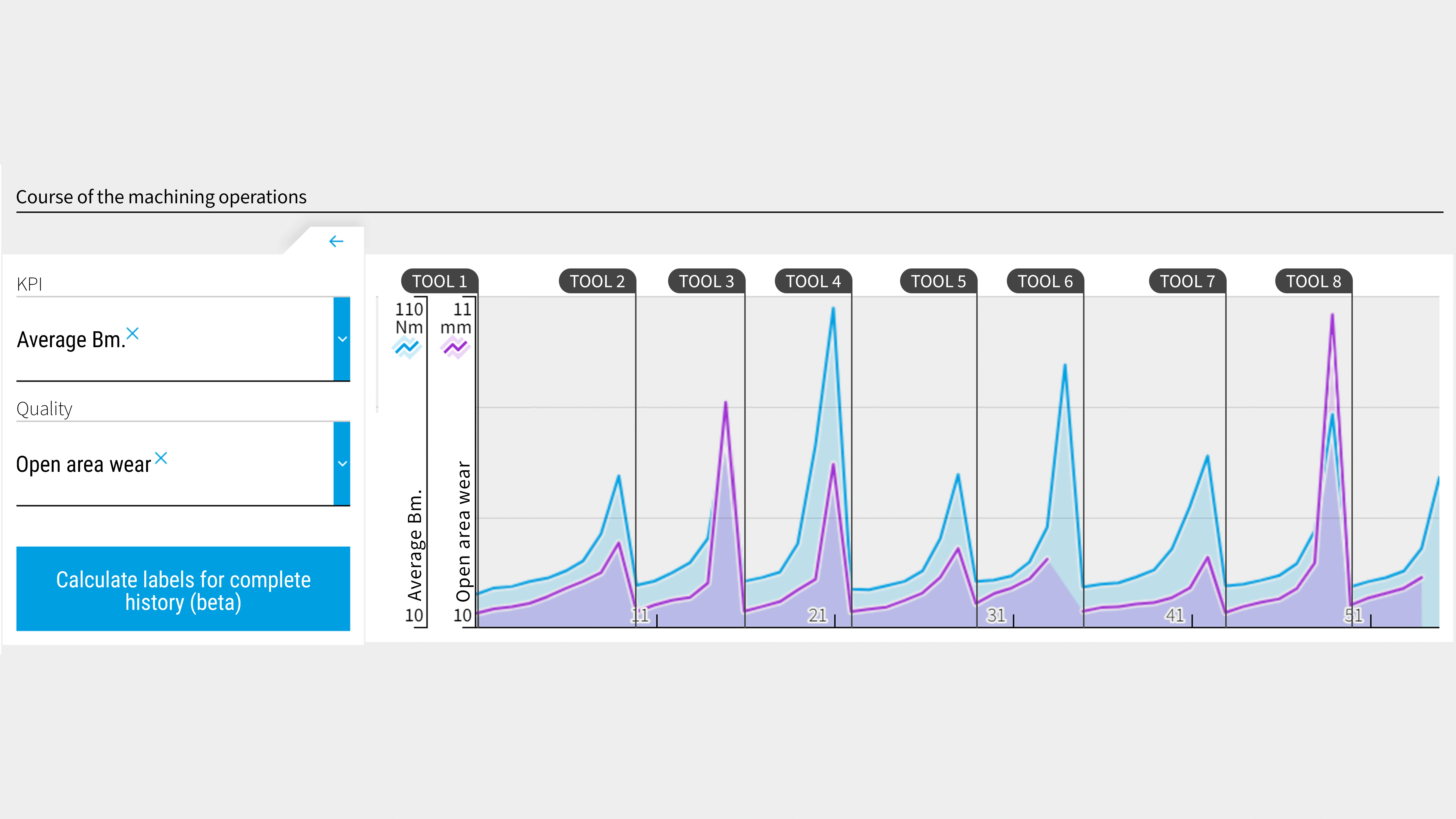

- Erstellen von Messreihen zur effizienten Langzeitdiagnose

- Detailanalyse von Einzelmessdateien inkl. spike®_polar Visualisierung

- Vergleiche & Gegenüberstellung von Messreihen/Messdaten (Einzel, Trends, „spike_polar-stacking“,.…)

- Automatisierte Berechnung von spike®_kpis (coming soon)

- Automatisierte Erstellung von Reports (coming soon)

- Automatisches Errechnen von Korrelationskoeffizienten zw. Mess- & Qualitätsdaten (coming soon)

- Nutzung von Datenbankeigenschaften zur effizienten Datenauswertung

spike® Kontakt

PRODUKT-ANFRAGEN

Lennart Riehle

Head of Sales (Tool Control)

Tel.: +49 8341 9560 – 50

inquiry(a)pro-micron.de